2025 Top Tips for Selecting the Best Through Valve for Your Needs

In the ever-evolving industrial landscape, the selection of the appropriate through valve remains a critical decision for optimizing fluid control systems. According to a recent industry report by MarketsandMarkets, the global valve market is expected to reach USD 90.7 billion by 2025, driven by the increasing need for efficient fluid handling across various sectors such as oil and gas, water and wastewater management, and chemical processing. Given this significant growth, understanding the nuances of through valves is essential for engineers and procurement specialists alike.

Through valves serve as integral components in regulating flow and ensuring system reliability. When selecting a through valve, it is essential to consider factors such as pressure rating, material compatibility, and specific application requirements. A comprehensive analysis reveals that improper valve selection can lead to increased maintenance costs and reduced system efficiency. As highlighted by the International Society of Automation, proper valve choice can enhance system performance by up to 20%, underscoring the importance of thorough research and informed decision-making.

This guide aims to equip professionals with top tips for choosing the most suitable through valve, ensuring that operational effectiveness and safety standards are achieved while navigating the complexities of modern fluid management systems.

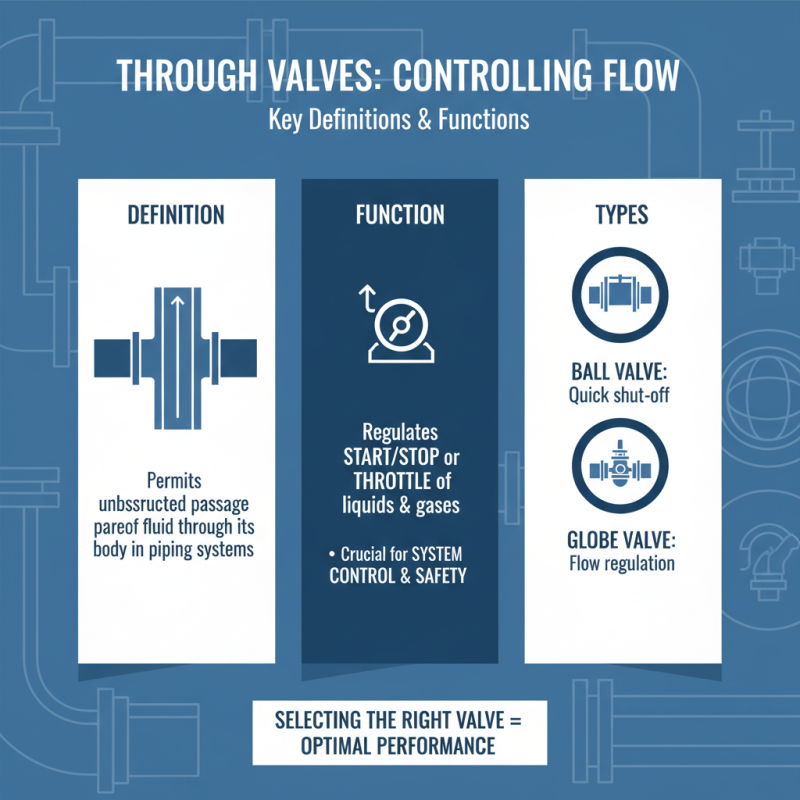

Guide to Understanding Through Valves: Key Definitions and Functions

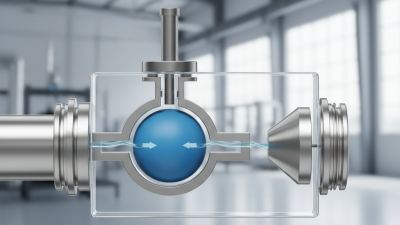

Through valves are crucial components in various piping systems, serving the essential function of controlling the flow of liquids and gases. Understanding their key definitions and functions is vital for effectively selecting the right valve for specific applications. A through valve, typically installed in a line where it permits passage through its body, can be categorized into different types, such as ball valves, gate valves, and globe valves, each designed with unique features to cater to diverse operational needs.

The primary function of a through valve is to regulate flow by either completely blocking or allowing passage. This operational flexibility makes through valves an indispensable part of manufacturing processes, water treatment facilities, and HVAC systems. It is important to consider factors such as pressure rating, material compatibility, and temperature range during selection to ensure optimal performance and longevity. By grasping these core concepts, industry professionals can make well-informed decisions when choosing through valves that align with their specific requirements and ensure system efficiency.

Factors to Consider When Choosing a Through Valve for Specific Applications

When selecting the best through valve for specific applications, several vital factors must be taken into account to ensure optimal performance and longevity. One key consideration is the valve's material compatibility with the media it will handle. According to the International Journal of Engineering Research and Technology, over 40% of valve failures are attributed to material corrosion and degradation in harsh environments. Thus, industries dealing with aggressive chemicals or extreme temperatures must select materials that offer adequate resistance, such as stainless steel or specialized alloys, to mitigate these risks.

Another critical aspect is the valve's flow characteristics and sizing. The American Society of Mechanical Engineers (ASME) suggests that improperly sized valves can lead to operational inefficiencies, resulting in up to 25% higher energy costs in large systems. Flow rate requirements, pressure drops, and system dynamics should be carefully analyzed to ensure suitable valve selection. Utilizing advanced computational fluid dynamics (CFD) modeling can provide valuable insights into flow patterns and help in selecting the right valve design, improving system reliability and performance.

Additionally, the operational environment and maintenance requirements play a decisive role in choosing the right through valve. Environments exposed to high levels of vibration or extreme conditions may require high-performance valves with robust features. Likewise, considering ease of maintenance is essential; valves that can be serviced without extensive disassembly can reduce downtime significantly. According to a report from the Valve Manufacturers Association, proper preventive maintenance can extend the life of valves by up to 50%, emphasizing the necessity of selecting valves that align with long-term operational strategies.

Material Selection: Choosing the Right Components for Durability and Performance

When selecting a through valve, material selection plays a crucial role in ensuring both durability and performance. The right materials can significantly affect the valve's resistance to corrosion, wear, and temperature changes, which are essential factors in various operating environments. Materials such as stainless steel, high-grade plastics, and various alloys are commonly used, and each has its unique advantages and limitations. For instance, stainless steel offers excellent resistance to harsh chemicals and high temperatures, while high-grade plastics may provide lighter options that can be better suited for certain applications involving less extreme conditions.

Furthermore, understanding the specific application of the valve is vital in making an informed material choice. Factors such as fluid type, pressure, and temperature must be analyzed to select a component that will perform reliably throughout its operational lifespan. For example, in applications involving aggressive chemicals, selecting a material with high chemical resistance can prevent premature failure and ensure consistent performance. Additionally, the environment where the valve will be installed—whether it's an outdoor setting subject to temperature fluctuations or in enclosed spaces with limited access—should also influence material selection to capitalize on the components’ durability and functionality. By carefully assessing these aspects, one can ensure that the through valve not only meets current needs but also stands the test of time.

2025 Top Tips for Selecting the Best Through Valve for Your Needs

| Material | Corrosion Resistance | Temperature Range (°F) | Pressure Rating (psi) | Typical Applications |

|---|---|---|---|---|

| Stainless Steel | Excellent | -420 to 1200 | 1500 | Oil & Gas, Chemical Processing |

| PVC | Moderate | 32 to 140 | 150 | Water Treatment, Irrigation |

| Cast Iron | Good | -20 to 400 | 250 | Water Supply, HVAC Systems |

| Brass | Moderate | -65 to 200 | 200 | Plumbing, Gas Applications |

| Carbon Steel | Fair | -20 to 600 | 3000 | Power Generation, Petrochemical |

Sizing Your Through Valve: Importance of Flow Rate and Pressure Requirements

When selecting the right through valve for your application, understanding the importance of flow rate and pressure requirements is crucial.

Flow rate refers to the volume of fluid that can pass through the valve in a given period, usually measured in liters per minute or gallons per hour. It's essential to choose a valve that can accommodate your system's maximum flow rate to ensure efficient operation. An undersized valve may lead to increased pressure drops and can compromise system performance, causing inefficiencies and potential failures.

Equally important is the consideration of pressure requirements. Valves must be engineered to withstand the specific pressure conditions of your system, including both the maximum and minimum pressures that may be experienced during operation.

Excessive pressure can lead to valve malfunction or even catastrophic failures, while insufficient pressure can hinder the flow and effectiveness of the process. Therefore, it's vital to analyze the pressure dynamics of your system and select a valve that not only fits these specifications but also provides a suitable safety margin to accommodate fluctuations. Taking these factors into account will ensure that you select a through valve that meets your operational needs reliably and efficiently.

Maintenance and Longevity: Best Practices for Extending Valve Life

When it comes to extending the longevity of through valves, regular maintenance is key. A proactive maintenance schedule not only helps in early identification of potential issues but also ensures that valves operate at optimal efficiency. Regular inspections to check for leaks, corrosion, and wear can help in preventing unexpected failures and costly downtime.

One of the top tips for maintaining your through valves is to ensure that they are operated within the specified pressure and temperature limits. Operating outside these parameters can lead to accelerated wear and reduce the lifespan of the valve. Additionally, routine lubrication based on manufacturer guidelines will help reduce friction and prevent mechanical failure.

Another essential practice is the implementation of a cleaning regimen. Depending on the application environment, valves can accumulate debris and contaminants that impair functionality. Regularly flushing the system and cleaning the exterior of the valves will help maintain seamless operation. Remember to always check seals and gaskets for wear and replace them as needed to prevent leaks and improve the overall performance of your valves.

2025 Top Tips for Selecting the Best Through Valve for Your Needs

This chart illustrates the key factors affecting the longevity of through valves, rated on a scale from 1 to 10. Ensuring high material quality and regular maintenance are critical to extending the life of your valves.

Related Posts

-

10 Best Ball and Globe Valves for Optimal Fluid Control in Industrial Applications

-

Top 10 Reasons Why Steel Ball Valves Are Essential for Your Industrial Applications

-

Unlocking the Benefits of Carbon Steel Ball Valves: A Comprehensive Guide to Selection and Usage

-

Top 10 Benefits of Floating Ball Check Valves You Need to Know

-

Top 10 Benefits of Trunnion Mounted Ball Valve for Your Industrial Applications

-

The Rising Demand for Globe Valves in Industrial Applications and Their Key Performance Metrics