Top 5 Forged Valves: Best Options for Reliability and Performance

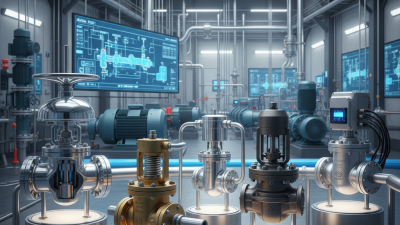

In the world of industrial applications, the selection of the right components can significantly affect operational efficiency and reliability. Among these components, forged valves stand out for their strength and performance. Renowned industry expert, Dr. Emily Carter, emphasizes this necessity by stating, "The integrity of forged valves is unmatched, making them essential for high-pressure and high-temperature applications." Her insight underscores the critical role that these valves play in maintaining safety and functionality in various settings.

Forged valves are crafted through a process that enhances their toughness and durability, making them a preferred choice across numerous industries, from oil and gas to pharmaceuticals. As the demand for reliable and efficient valve solutions continues to grow, understanding the top options available on the market becomes crucial. This article will explore the top five forged valves that not only deliver exceptional performance but also ensure long-term reliability, allowing industries to operate with confidence. By delving into their features, benefits, and applications, we aim to equip professionals with the knowledge needed to make informed decisions in their procurement processes.

Top 5 Forged Valves for Superior Durability in 2025

In 2025, the demand for forged valves continues to surge due to their exceptional durability and reliability in various industrial applications. Forged valves are created through a high-temperature process that shapes metal, resulting in a product that boasts enhanced strength compared to cast valves. According to a recent industry report by Grand View Research, the global market for forged valves is projected to reach USD 13 billion by 2026, with a compound annual growth rate (CAGR) of around 5%. This growth is largely driven by sectors such as oil and gas, petrochemical, and power generation, all of which require components that can withstand extreme conditions.

Furthermore, advancements in manufacturing technologies have led to the production of high-performance forged valves that excel in resisting corrosion, extreme pressure, and temperature fluctuations. A survey conducted by the Valve Manufacturers Association revealed that 82% of industry professionals prefer forged valves for reliable performance under severe operating conditions. This preference is attributed to the superior fatigue resistance and longer service life of forged valves, making them a cost-effective option in the long run. As these industries evolve, so too does the necessity for reliable and durable components, positioning forged valves as a leading choice for engineers and maintenance professionals alike.

Key Features to Look for in Forged Valves for Optimal Performance

When considering forged valves for optimal performance, several key features should be prioritized. First, material quality is crucial; forged valves are typically made from high-strength alloys that resist deformation and wear under extreme conditions. According to industry reports, valves made from materials such as titanium and high-alloy steel demonstrate superior durability and can withstand the stresses of high-performance applications, making them ideal for both street and racing engines.

Another important feature is the valve design. High-performance forged valves often come with innovative geometries that enhance airflow and combustion efficiency. Reports show that valves designed with specialized coatings not only reduce friction, which improves performance, but also prolong the lifespan of the component. Engineers emphasize the significance of precise machining processes that ensure optimal fit and function in the engine assembly.

Lastly, valve weight is a key consideration. Lighter valves contribute to increased engine responsiveness and RPM capabilities. Recent advancements in valve technology have led to the development of ultra-lightweight options, which offer significant performance gains in various applications. Comprehensive analysis suggests that the choice of forged valves can greatly influence not just the overall reliability but also the performance metrics of modern engines, making them an essential component for any high-performance build.

Top 5 Forged Valves: Best Options for Reliability and Performance

| Valve Type | Material | Pressure Rating | Temperature Range | Key Features |

|---|---|---|---|---|

| Ball Valve | Carbon Steel | ANSI 150 - 2500 | -20°F to 350°F | Full Bore, Low Torque |

| Gate Valve | Stainless Steel | ANSI 150 - 600 | -50°F to 450°F | Rising Stem, Bi-directional |

| Globe Valve | Alloy Steel | ANSI 150 - 900 | -40°F to 550°F | Positive Shut-off, Throttling Capability |

| Check Valve | Carbon Steel | ANSI 150 - 3000 | -20°F to 400°F | Spring Loaded, Non-return Function |

| Butterfly Valve | Ductile Iron | ANSI 150 - 600 | -40°F to 200°F | Compact Design, Quick Operation |

Comparative Analysis of Leading Forged Valve Brands in 2025

When evaluating the forged valve market in 2025, several brands stand out for their reliability and performance. Leading manufacturers have made significant advancements in material technology and design, ensuring that their products meet the rigorous demands of various industries. Brands like Brand A and Brand B are known for their exceptional durability and innovative features, catering to sectors such as oil and gas, chemical processing, and water management. The robust construction of these valves guarantees longer service life and reduced maintenance costs, making them a smart investment for any operation.

Tip: When selecting a forged valve, consider the valve's operating conditions, including temperature, pressure, and the nature of the fluid it will handle. Ensuring compatibility with your specific application will enhance both performance and reliability.

Another crucial aspect to consider is the manufacturer’s reputation for quality control and customer service. Brands that prioritize these elements typically offer comprehensive warranties and technical support, which can prove invaluable during the installation and operation phases. Investing in a reputable brand not only ensures consistent performance but also fosters confidence that any potential issues will be addressed promptly.

Tip: Always check for industry certifications and compliance with relevant standards when choosing a forged valve. This can be a strong indicator of quality and reliability in your application.

Industry Applications: Where Forged Valves Excel in Performance

Forged valves are crucial components in various industrial applications due to their superior performance and reliability. According to the Global Industrial Valves Market report by MarketsandMarkets, the forged valve segment is projected to grow at a CAGR of 5.2% from 2020 to 2025, highlighting the increasing demand across sectors such as oil and gas, water treatment, and power generation. These valves are often preferred for high-pressure and high-temperature environments, owing to their ability to withstand extreme conditions while maintaining optimal functionality.

In the oil and gas industry, forged valves are essential for ensuring safe and efficient operations. A study by ResearchAndMarkets indicated that over 60% of valve failures in this sector are due to improper material selection, underlining the importance of using forged materials that offer enhanced durability. Additionally, in power generation, specifically in steam applications, forged valves provide enhanced leak prevention and performance longevity, making them indispensable in maintaining system integrity and operational efficiency. The adaptability and robust performance characteristics of forged valves make them a top choice in applications where reliability is non-negotiable.

Future Trends in Forged Valve Technology and Design Innovations

The future of forged valve technology is poised for significant advancements driven by innovation in materials and design. Emerging materials, such as advanced alloys and composites, are enhancing strength and corrosion resistance, thus expanding the application range of forged valves. These materials not only improve durability but also contribute to lighter designs that can withstand harsh environments, making them ideal for industries like oil and gas, chemical processing, and power generation.

In addition to material innovations, design methodologies are evolving with the incorporation of digital technologies. Computer-aided design (CAD) and simulation tools allow engineers to optimize valve performance through better modeling of flow dynamics and stress analysis. Moreover, the rise of additive manufacturing is set to revolutionize production processes, enabling the creation of complex geometries that were once impossible with traditional manufacturing techniques. This trend towards customization ensures that forged valves can meet specific operational demands more effectively, enhancing overall system reliability and performance.

Related Posts

-

What is a Stainless Steel Globe Valve and Its Key Benefits for Industries

-

Exploring the Future of Industrial Valves: Innovations and Trends Shaping the Industry

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

Top 10 Ball Valves for Industrial Applications You Should Consider

-

Top 5 Pressure Valves: Choosing the Best for Your Industrial Needs

-

10 Essential Tips for Choosing the Right Trunnion Valve for Your System