Top 10 Tips for Choosing the Best Industrial Check Valves for Your Needs

When it comes to ensuring efficiency and safety in industrial processes, selecting the right industrial check valves is crucial. These devices play an essential role in controlling fluid flow and preventing backflow, which can lead to system failures and costly downtime. However, with a multitude of options available on the market, making an informed decision can be challenging. Understanding the specific requirements of your application, such as pressure ratings, materials, and operational conditions, is imperative to choose the best industrial check valves for your needs.

This guide will provide you with valuable insights and practical tips to navigate the selection process. By considering factors such as the type of fluid, installation environment, and maintenance requirements, you’ll be better equipped to make a choice that aligns with your operational goals. Whether you are looking to enhance performance, ensure safety, or optimize costs, the right industrial check valves can make all the difference in achieving reliable and efficient system operation.

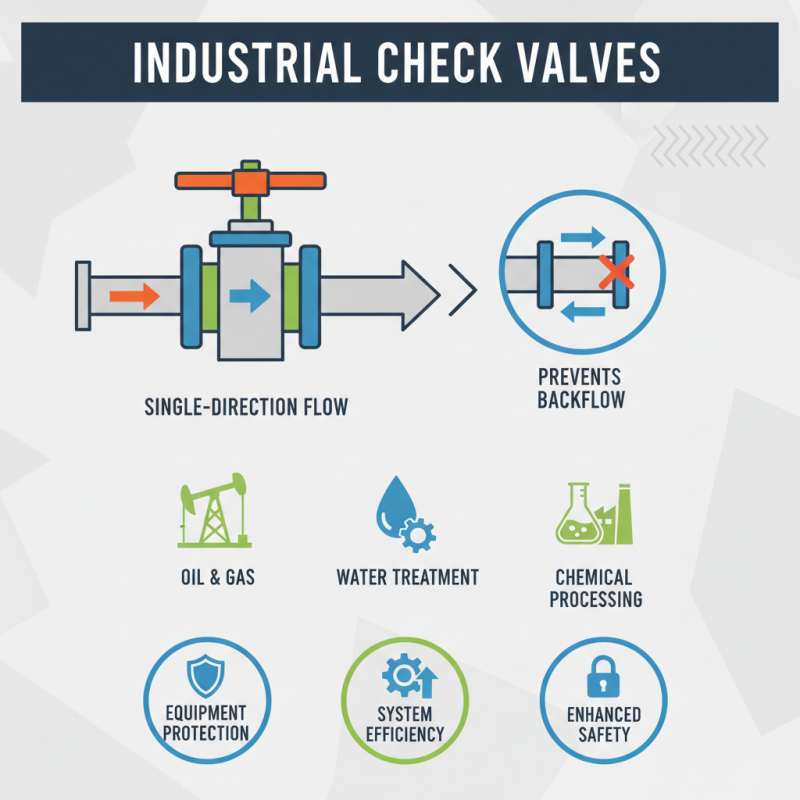

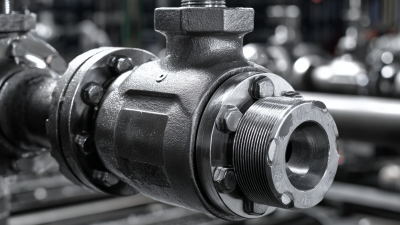

Understanding the Role of Industrial Check Valves in Fluid Control

Industrial check valves play a crucial role in fluid control systems, primarily by ensuring that fluids flow in a single direction and preventing backflow. These valves are essential components in various applications, including oil and gas, water treatment, and chemical processing. They rely on a simple design that automatically opens and closes, responding to changes in fluid pressure. By doing so, they protect equipment, maintain system efficiency, and enhance safety in industrial operations.

Understanding the specific requirements of your application is vital when selecting a check valve. Factors such as the type of fluid, pressure levels, temperature fluctuations, and the potential for debris in the system must all be considered. The right choice of check valve can lead to improved operational performance and reduced maintenance costs. Ultimately, selecting an appropriate industrial check valve is not just about functionality; it’s about integrating a reliable solution into your fluid management strategy to achieve optimal results.

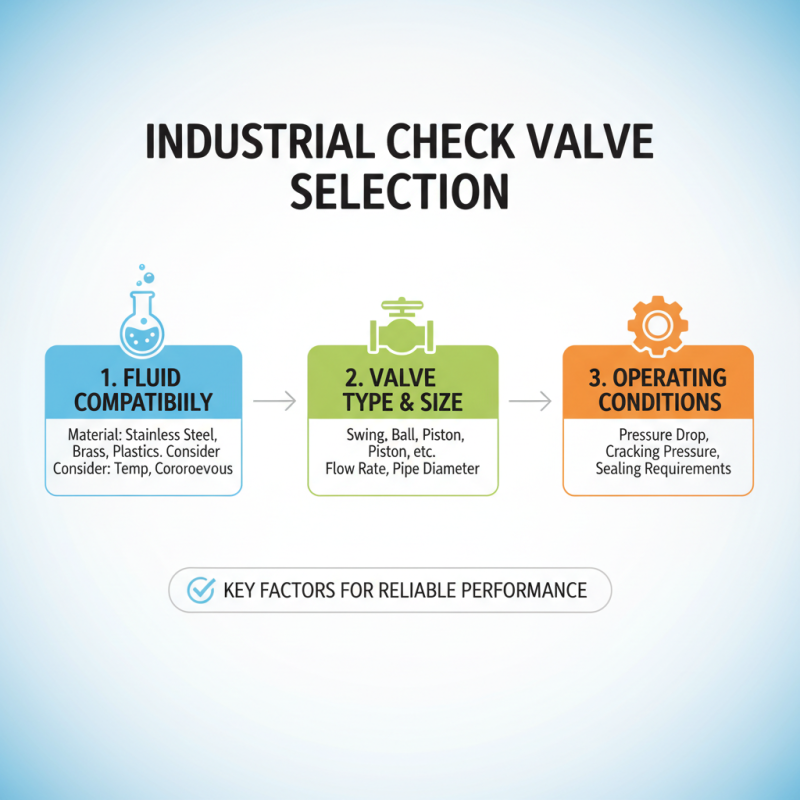

Key Factors to Consider When Selecting Industrial Check Valves

When selecting industrial check valves, several key factors play a crucial role in ensuring that you make the right choice for your specific needs. First and foremost, consider the valve's material compatibility with the fluids it will regulate. Common materials include stainless steel, brass, and various plastics, each offering different levels of corrosion resistance and suitability for specific chemical environments. Assessing the fluid's characteristics, such as temperature, pressure, and corrosiveness, will help you determine the most appropriate material for your application.

Another vital factor is the valve's flow rate and pressure drop characteristics. Check valves are designed to allow fluid to flow in one direction while preventing backflow, but their efficiency often depends on the application requirements. Look for valves that can handle your system's flow rate without causing significant pressure drops, which can impact overall system performance. Additionally, consider the size and installation requirements of the valve, ensuring that it fits within your existing piping system and meets the necessary standards for your industry.

Material Compatibility: Choosing the Right Construction for Your Application

When selecting industrial check valves, material compatibility is critical to ensuring optimal performance and longevity in specific applications. Different materials, such as stainless steel, brass, plastic, and various alloys, provide varying degrees of resistance to chemicals, temperature, and pressure. Industry data indicates that approximately 70% of valve failures are due to material incompatibility, underscoring the importance of making informed choices based on the environment in which the valve will operate. For instance, if the valve is intended for use with corrosive substances, opting for materials with high corrosion resistance, such as 316 stainless steel or specially coated alloys, is essential.

One tip for selecting materials is to thoroughly analyze the media being transported. Understanding the chemical composition and properties of the fluid can significantly influence the chosen material. Additionally, consider the operating conditions—high temperatures and pressures may require specially designed materials that can withstand extreme stress without deforming. It’s also advisable to consult compatibility charts and guides developed by industry professionals; these resources provide valuable insights into how different materials behave in various environments, helping to prevent costly mistakes.

Another critical tip is to assess the longevity and maintenance requirements of potential materials. According to data from industry experts, the cost of replacement components and labor often exceeds initial valve investment—up to 50% of lifecycle costs. Therefore, selecting durable materials that require minimal maintenance can lead to significant savings over time. By prioritizing material compatibility and understanding the specific demands of your application, you can make more informed decisions in choosing the best industrial check valves for your needs.

Material Compatibility for Industrial Check Valves

Flow Rate and Pressure Ratings: Ensuring Optimal Performance

When selecting industrial check valves, understanding flow rate and pressure ratings is paramount to ensuring optimal performance in your system. Flow rate, expressed in terms of gallons per minute (GPM) or liters per second (L/s), indicates how much fluid can pass through the valve without causing excessive turbulence that might lead to inefficiencies or potential damage. A valve that matches the specific flow rate requirements of your application will help maintain system balance and reduce the likelihood of cavitation or noise, both of which can significantly impact operation and longevity.

Equally important are the pressure ratings associated with check valves. These ratings define the maximum pressure the valve can safely handle while maintaining its integrity and performance. Selecting a valve with a pressure rating suitable for your application is critical, as exceeding this can lead to leaks, failures, or catastrophic breakdowns. It's essential to consider not only the normal operating conditions but also any potential pressure surges that may occur during operation.

By carefully evaluating both flow rates and pressure ratings, you can choose check valves that ensure reliability, efficiency, and durability in your industrial processes.

Maintenance and Inspection: Ensuring Longevity of Your Check Valves

Ensuring the longevity of check valves in industrial applications necessitates a robust maintenance and inspection routine. Regular inspections should focus on identifying signs of wear, corrosion, or accumulation of debris that could impede the valve's operation. This includes checking the seals for integrity, examining the surfaces for cracks, and ensuring there are no obstructions preventing the valve from closing properly. By scheduling these inspections at regular intervals, operators can detect potential issues early, mitigating costly repairs and downtime.

Maintenance practices for check valves typically encompass cleaning, lubrication, and, if necessary, replacement of worn components. Cleaning should involve removing any accumulated deposits that might affect valve performance. In instances where the valve operates in a challenging environment, such as high-pressure or corrosive conditions, a more frequent maintenance schedule is advisable. Additionally, ensuring that all maintenance activities are meticulously documented can assist in tracking the valve's performance over time and inform necessary adjustments to the maintenance frequency as operational conditions evolve. In this way, a well-maintained check valve not only functions optimally but also contributes to overall system reliability.

Top 10 Tips for Choosing the Best Industrial Check Valves for Your Needs - Maintenance and Inspection: Ensuring Longevity of Your Check Valves

| Tip Number | Tip | Description | Frequency of Maintenance |

|---|---|---|---|

| 1 | Material Selection | Choose valves made from materials compatible with the application to prevent corrosion. | Annually |

| 2 | Size Appropriateness | Ensure the valve size matches the piping system to maintain flow efficiency. | Bi-Annually |

| 3 | Pressure Ratings | Select check valves that can withstand the pressure levels of the system. | Annually |

| 4 | Flow Direction | Verify flow direction markings on valves to avoid installation errors. | Inspect during installation |

| 5 | Low Maintenance Features | Choose valves designed for minimal maintenance to improve longevity. | Every 2 years |

| 6 | End Connections | Ensure the valve's end connections are compatible with your piping system. | Inspect during installation |

| 7 | Temperature Resistance | Select valves that can operate efficiently within the temperature range of the system. | Annually |

| 8 | Check Valve Type | Choose the appropriate type of check valve for the specific application (e.g., swing, lift). | As needed |

| 9 | Installation Practices | Ensure proper installation practices are followed to avoid premature wear. | During installation |

| 10 | Regular Inspections | Conduct regular inspections to catch issues before they become serious. | Quarterly |

Related Posts

-

Understanding the Essential Role of Trunnion Valves in Modern Industrial Applications

-

2025 How to Choose the Right Stainless Steel Valves for Your Industry Needs

-

How to Choose the Right Trunnion Ball Valve for Your Application

-

Unlocking the Benefits of Carbon Steel Ball Valves: A Comprehensive Guide to Selection and Usage

-

10 Essential Tips for Choosing the Right Trunnion Valve for Your System

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems