Why Is Swing Check Valve Essential for Efficient Fluid Control?

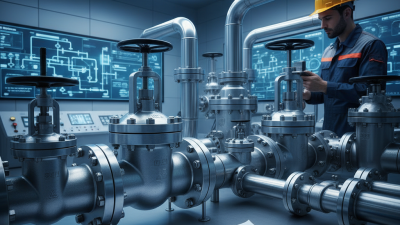

In fluid control systems, efficiency is paramount. The choice of components can greatly influence performance. One critical component is the swing check valve. This valve plays a vital role in ensuring fluid flows in the right direction without backflow.

Swing check valves use a simple mechanism, with a disc that swings open and closed. Their design minimizes the pressure drop within the system. This is crucial in industrial applications where fluid control is key. Often, however, users overlook the importance of maintenance. Neglecting regular checks can lead to failures and inefficiencies.

Understanding the significance of swing check valves can enhance operational efficiency. Their ability to prevent backflow protects equipment and maintains system integrity. Investing time in proper selection and care of these valves is essential. It's an area where many could improve.

Understanding Swing Check Valves and Their Functionality

Swing check valves play a crucial role in fluid control systems. These devices allow fluid to flow in one direction, preventing backflow. This functionality is vital in various applications, such as water supply and wastewater management. In many systems, backflow can lead to contamination. Thus, using a swing check valve enhances safety and reliability.

The design of a swing check valve is quite interesting. It features a hinged disc that opens with water flow and closes when the flow reverses. This mechanism ensures that the valve responds quickly. Regular inspection is important, though. Over time, dirt or wear can affect its performance. A stuck valve can result in costly repairs or system failures.

Installation location also matters. Placing a swing check valve in the wrong position can impair its efficiency. It’s vital to consider the flow direction and pressure rating during setup. Often, maintenance practices are overlooked, leading to unexpected issues. Ensuring proper upkeep can prolong the life of the valve and improve system efficiency.

Importance of Swing Check Valves for Efficient Fluid Control

Key Advantages of Using Swing Check Valves in Fluid Systems

Swing check valves play a crucial role in fluid systems. Their design enables efficient flow control while preventing backflows. According to a report by the Fluid Control Association, improper flow management costs industries billions annually. This highlights the necessity of implementing effective solutions like swing check valves.

One key advantage is their simplicity. These valves have a straightforward mechanism that minimizes maintenance needs. They can handle various fluids, making them versatile for systems across sectors. In fact, a study by the American Society of Mechanical Engineers shows that swing check valves can increase system reliability by up to 30%.

Tips: Always consider the fluid type. Underestimating fluid properties may lead to valve failure. Installation position is vital, too. A poorly installed valve can disrupt flow dynamics. Regular checks can help in identifying potential issues early. Consider integrating usage data to enhance efficiency.

Why Is Swing Check Valve Essential for Efficient Fluid Control? - Key Advantages of Using Swing Check Valves in Fluid Systems

| Advantage | Description | Applications |

|---|---|---|

| Backflow Prevention | Prevents reverse flow of fluids, ensuring system integrity and safety. | Pipelines, Pumps, Water Treatment |

| Low Pressure Drop | Designed to minimize pressure loss in the system during fluid flow. | Industrial Processes, HVAC Systems |

| Durability | Constructed from robust materials to withstand harsh operating conditions. | Chemical Processing, Oil & Gas |

| Simple Design | Fewer moving parts result in easier maintenance and repair. | Water Supply, Fire Protection Systems |

| Versatile Installation | Can be installed in any orientation, adding flexibility to system design. | Various Fluid Transport Systems |

Applications of Swing Check Valves in Various Industries

Swing check valves play a crucial role in various industries, ensuring proper fluid control. Their primary function is to allow flow in one direction while preventing backflow. This is vital in sectors such as water treatment, oil and gas, and food processing. According to a recent report, about 30% of pipeline failures are attributed to backflow issues. This highlights the need for reliable check valves in maintaining system integrity.

In the water treatment industry, swing check valves help regulate flow in treatment plants. They minimize water loss and enhance operational efficiency. For instance, a study indicates that proper valve installation can reduce water waste by up to 15%. In oil and gas, these valves protect against pressure surges. A malfunctioning valve could result in hazardous leaks, emphasizing their importance.

However, selecting the right valve isn't always straightforward. Factors like fluid type and pressure conditions must be considered. In some cases, professionals overlook the maintenance of these valves. Regular inspections could prevent failures and save costs. By understanding applications and maintaining swing check valves, industries can improve efficiency and safety significantly.

Maintenance and Troubleshooting of Swing Check Valves

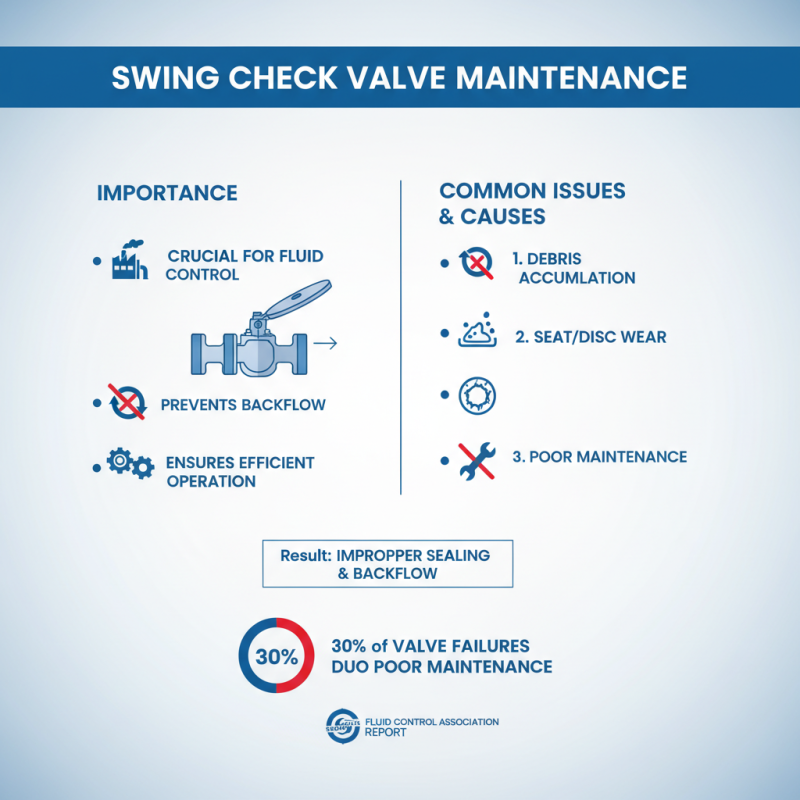

Swing check valves are crucial for effective fluid control in various industries. However, they require regular maintenance to function efficiently. Common issues include debris accumulation and wear on the seat. These can lead to improper sealing, resulting in backflow. A report by the Fluid Control Association highlights that 30% of valve failures occur due to poor maintenance.

Routine inspection should focus on the valve's operating environment. Ensure there is no buildup of materials that can hinder performance. Keep an eye on the valve's condition, as visual signs of wear can indicate the need for replacement.

Tips: Always clean valves during maintenance. Use appropriate solvents to avoid damage. Regularly test the pressure drop across the valve to assess its performance. Document all findings, as this information can help identify patterns in valve failure.

Ignoring maintenance can lead to unexpected downtime and costly repairs. Be proactive in addressing minor issues before they escalate. Regular training for staff on troubleshooting can also enhance maintenance practices. Invest in quality tools for routine checks to ensure reliable operation.

Comparing Swing Check Valves with Other Types of Check Valves

Swing check valves are vital in various fluid control applications. They are designed to allow fluid flow in one direction while preventing backflow. Unlike other check valve types, such as globe or ball check valves, swing check valves have a simpler mechanism. This makes them ideal for larger pipes where flow is substantial. A study from the American Society of Mechanical Engineers states that swing check valves can reduce energy costs by up to 20% in certain systems.

However, swing check valves are not without limitations. They depend on gravity and flow velocity to function effectively. In low-flow scenarios, they may not seal properly. This can result in backflow, leading to inefficiencies. A report by the International Journal of Fluid Mechanics indicates that improperly selected check valves can cause a 30% drop in system performance. In contrast, ball check valves may handle low flow better due to their design.

Proper installation and maintenance are crucial. Swing check valves require less maintenance compared to other types but must be monitored. If debris accumulates, it can hinder performance. The decision on valve type should consider flow characteristics, installation space, and maintenance needs.

Related Posts

-

Top 5 Best Ball Check Valves for Efficient Fluid Control?

-

How to Choose the Right Ball Check Valve for Your Plumbing Needs

-

The Essential Guide to Choosing the Right Floating Valve for Your Water Systems

-

The Best 10 Ball Check Valve Options for Efficient Fluid Control

-

Top 10 Stainless Steel Valves for Every Application You Need to Know

-

2025 How to Choose the Right Steel Ball Valve for Your Industrial Needs