How to Choose the Right Swing Valve for Your Application?

When selecting the right swing valve for your application, various factors come into play. According to the Valve Manufacturers Association, the global valve market is expected to reach $80 billion by 2026, highlighting the growing importance of choosing the right components. Swing valves are crucial in many sectors, including water treatment, oil and gas, and chemical processing. Industry expert Dr. James Williams states, "A well-chosen swing valve can optimize system performance and enhance operational efficiency."

However, the process of selection can be daunting. With numerous designs, materials, and sizes available, the risk of making the wrong choice increases. This misstep can lead to leaks, increased maintenance costs, and even system failures. Many companies still struggle to choose the correct specifications. In fact, a survey by the International Valve Association revealed that 30% of valve failures are due to improper selection.

Understanding the specific requirements of your system is imperative. Consider factors such as pressure ratings, temperature ranges, and medium type. A swing valve that works well in one application may not be suitable for another. Take time to assess all conditions. Balancing the technical specifications with operational needs can result in a more effective and reliable installation.

Understanding Swing Valves and Their Applications

Swing valves play a crucial role in various industrial applications. They are designed to control the flow of liquids and gases. Understanding their functionality is essential for effective implementation. Swing valves operate by using a disc that swings on a hinge. This design allows for a smooth flow when open. However, during certain conditions, they may not seal effectively. This can lead to unintended leaks.

Applications for swing valves vary widely. They are commonly used in water supply systems, HVAC units, and oil pipelines. In a water treatment plant, a swing valve controls the flow to different sections. If improperly selected, it can cause inefficiencies. For instance, a valve that is too small may lead to increased pressure and potential damage. Alternatively, a large valve may result in inadequate control.

Choosing the right swing valve depends on pressure, temperature, and flow characteristics. Each application has unique requirements. Overlooking specifics can have significant consequences. Not all swing valves suit every environment. Users must assess their needs carefully. An exact fit ensures optimal performance. Adjustments might be necessary after installation, highlighting the complexity involved in valve selection.

How to Choose the Right Swing Valve for Your Application?

| Application | Valve Size (inch) | Pressure Rating (PSI) | Material | Temperature Range (°F) |

|---|---|---|---|---|

| Water Treatment | 2 | 150 | Stainless Steel | 33 - 150 |

| Oil & Gas | 4 | 600 | Carbon Steel | -20 - 300 |

| HVAC Systems | 1.5 | 250 | Bronze | 32 - 180 |

| Chemical Processing | 3 | 300 | PVC | -10 - 140 |

| Food & Beverage | 1 | 150 | 316 Stainless Steel | 32 - 250 |

Key Factors to Consider When Selecting a Swing Valve

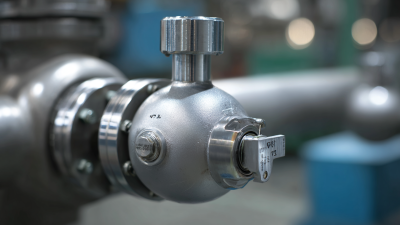

When selecting a swing valve, it's crucial to evaluate several key factors. The valve size is a primary consideration. It should match the pipeline diameter to ensure proper flow. An incorrectly sized valve can lead to inefficiencies or even system failures. The valve material also matters. Different applications may require materials that resist corrosion or withstand high temperatures. Stainless steel is popular, but other options exist.

Another vital aspect is the pressure rating. Understanding the operating pressure of your system helps in choosing a durable valve. A valve with a low pressure rating could fail prematurely. Don't overlook the operational environment. Dust, moisture, and temperature fluctuations can impact performance. If the environment is harsh, opt for valves designed for those conditions.

Installation complexity is another factor. Some swing valves may need elaborate setups, which can be costly. Ensure the selected valve aligns with your installation capability. Maintenance requirements also vary. Regular upkeep is essential for performance, so consider how easy it is to access and service the valve. The more thought you put into these elements, the smoother your operation will be.

Comparing Different Types of Swing Valves

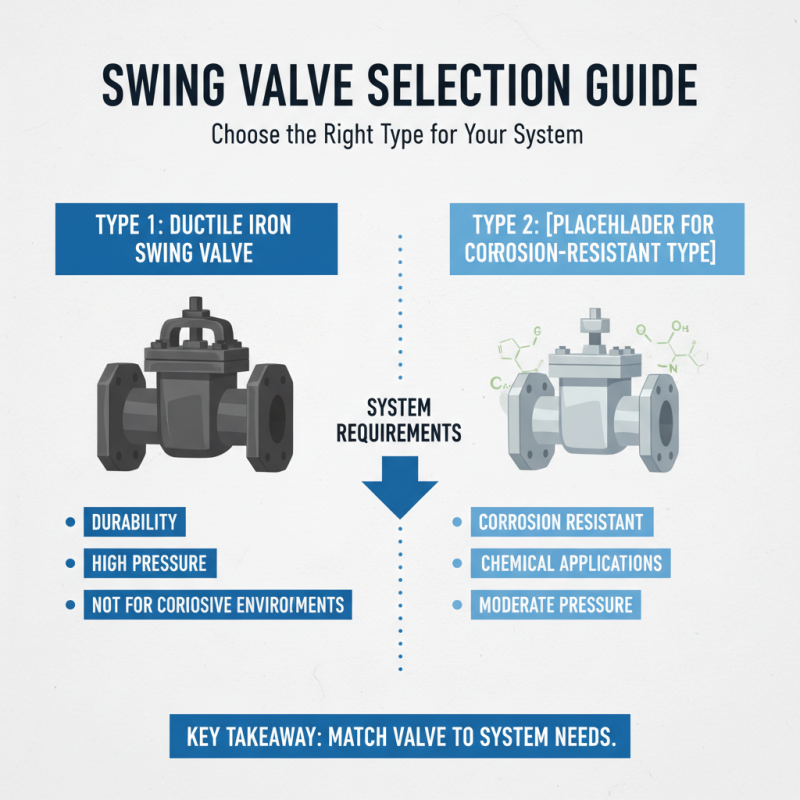

When it comes to swing valves, selecting the correct type is crucial for your system's performance. There are several types of swing valves, each designed for specific functions. For instance, the ductile iron swing valve is known for its durability and ability to handle high pressure. However, it might not be the best fit for corrosive environments.

Another option is the stainless steel swing valve. This type offers excellent resistance to corrosion and is ideal in harsh conditions. Yet, these valves can be more expensive. It's essential to weigh factors like cost, material compatibility, and pressure rating when making a decision.

Some applications may benefit from a low-torque swing valve. These valves require less force to operate, simplifying installation and maintenance. However, they might not perform well under extreme pressure. Each type has its pros and cons, emphasizing the importance of understanding your specific needs. Consider consulting industry guidelines to avoid common pitfalls in selection.

Installation and Maintenance Tips for Swing Valves

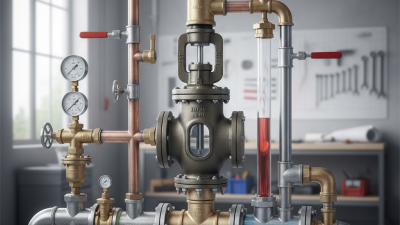

When installing swing valves, proper placement is key. Ensure valves are located where they can function effectively. For optimal performance, the swing valve should be mounted at an angle, allowing for natural flow. According to industry reports, improper installation can lead to a 30% drop in efficiency. A common mistake is neglecting to check for debris in pipelines before installation. This can cause wear and tear on the valve.

Maintenance is crucial for longevity. Regular inspections can identify wear early. Reports suggest that proactive maintenance can extend a valve’s life by 25%. Checking seals and actuators every six months can prevent costly failures. Also, keep an eye on the valve's response time. A delay could signal underlying issues. Ignoring these signs may lead to complete valve failure, which is far more costly.

Finally, ensure that staff is trained in installation and maintenance practices. A lack of knowledge can result in errors. Regular training sessions can help mitigate this risk. The industry average indicates that companies with trained staff reduce installation errors by nearly 40%. Take time to assess your processes. Continuous improvement is essential for efficiency and safety.

Hydraulic Swing Valve Selection Criteria

This chart illustrates the importance of different criteria when selecting a swing valve for hydraulic applications. The data reflects a weighted score based on industry feedback regarding critical factors such as pressure rating, material compatibility, size, and cost-efficiency.

Common Mistakes to Avoid When Choosing a Swing Valve

When selecting a swing valve, many mistakes can hinder performance. One common error is overlooking the media type. Different fluids have varying properties. For instance, steam and corrosive chemicals require specific materials. According to a report by the American Society of Mechanical Engineers, nearly 30% of valve failures relate to incorrect material choices.

Another frequent oversight involves pressure ratings. Some users do not consider operating conditions adequately. Limited pressure can lead to leaks or even breakage. The Valve Manufacturers Association indicates that about 40% of valve issues arise from exceeding pressure limits. Checking the system's specifications thoroughly is crucial for optimal functionality.

Additionally, size matters significantly. A valve that is too small can restrict flow. Conversely, an oversized valve may not seal properly, leading to inefficiencies. A study from the International Journal of Fluid Mechanics highlighted that incorrect sizing can result in up to 20% energy loss in broader systems. It's essential to measure accurately before making a decision.

Related Posts

-

How to Choose the Right Swing Check Valve for Your Plumbing Needs

-

Top 10 Ball Valves for Industrial Applications You Should Consider

-

The Best 10 Ball Check Valve Options for Efficient Fluid Control

-

Top 5 Forged Valves: Best Options for Reliability and Performance

-

Top 10 Tips for Choosing the Best Industrial Check Valves for Your Needs

-

10 Best Ball and Globe Valves for Optimal Fluid Control in Industrial Applications