How to Choose the Right Swing Check Valve for Your Plumbing Needs

When it comes to plumbing systems, ensuring proper flow control and backflow prevention is crucial for maintaining efficiency and safety. One key component often utilized for this purpose is the swing check valve. Unlike other types of check valves, the swing check valve operates on a simple mechanism that allows fluid to flow in one direction while simultaneously preventing backflow. Selecting the right swing check valve is essential for the overall functionality of your plumbing setup, as an improper choice can lead to leaks, system inefficiencies, or even damage to your pipes.

To make an informed decision, one must consider several factors, including the size of the valve, the type of fluid being transported, and the specific pressure requirements of the system. Understanding these parameters will not only help in selecting the right swing check valve but will also ensure longevity and reliability in your plumbing system. This introduction sets the stage for a comprehensive exploration of factors influencing the selection process and the best practices for incorporating swing check valves into your plumbing needs.

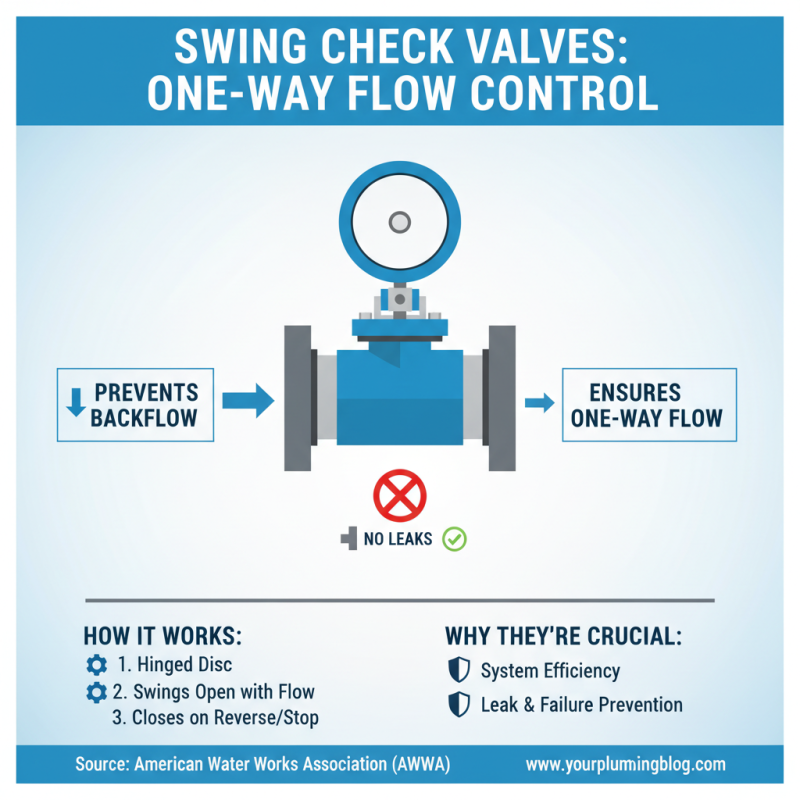

Understanding Swing Check Valves and Their Functionality

Swing check valves are crucial components in many plumbing systems, providing a one-way flow of fluids and preventing backflow. Understanding how these valves function is essential for selecting the right one for your specific needs. These devices operate through a hinged disc that swings open with the flow of liquid and closes when flow stops or reverses. According to the American Water Works Association, improper installation or the wrong type of valve can lead to inefficiencies, leaks, or even system failures.

When choosing a swing check valve, consider the material, pressure rating, and size. Brass, stainless steel, and PVC are common materials, each suitable for different applications. For instance, stainless steel valves are often preferred in high-pressure systems, while PVC may be sufficient for low-pressure applications. Industry data shows that system efficiency can be impacted by up to 30% when the wrong valve is employed. Therefore, it’s critical to ensure the valve you select can handle the specific demands of your plumbing system.

**Tips: Always verify the maximum pressure and temperature ratings of the valve to match your system requirements, and take into account the fluid type, as corrosive substances may necessitate specific materials. Additionally, ensure that the valve is installed in the correct orientation, as reversing the installation can lead to malfunctions.**

Identifying Your Plumbing System Requirements

When selecting the appropriate swing check valve for your plumbing system, it's crucial to first identify the specific requirements of your plumbing configuration. Parameters such as fluid type, pressure conditions, temperature ranges, and the size of your piping all play significant roles in determining the most suitable valve. According to a report by the American Society of Plumbing Engineers (ASPE), incorrect sizing is one of the most common issues leading to inefficiencies in plumbing systems. Ensuring that the swing check valve matches the diameter of the connected pipes and can handle the necessary flow rate is essential for optimal performance.

Additionally, understanding the operational environment of your plumbing system is vital. Swing check valves are often subjected to varying pressures and temperatures, which can affect their functionality over time. The Hydraulic Institute suggests that for applications involving high pressure or temperature fluctuations, choosing a valve made from materials with higher resistance to corrosion and wear can lead to a longer service life. It is also important to consider whether your system is gravity-driven or requires a specific flow direction, as this will influence the design and orientation of the valve. By comprehensively evaluating these factors, you can ensure that your plumbing system operates efficiently and effectively.

Understanding Swing Check Valve Selection Based on Flow Rate

This bar chart illustrates the relationship between the size of swing check valves and their respective flow rates in gallons per minute (GPM). Choosing the right size for your plumbing needs is essential to ensure effective operation and prevent backflow.

Factors to Consider When Selecting a Swing Check Valve

When selecting a swing check valve for your plumbing needs, several critical factors must be taken into account to ensure optimal performance. First, it's essential to consider the fluid characteristics, including temperature, pressure, and type of fluid. Different materials are suitable for various fluid types; hence, knowing whether your system handles water, oil, or chemicals will guide you in choosing the right valve construction, such as stainless steel, PVC, or brass.

Another important factor is the valve size and flow capacity. The diameter of the valve should match your piping system to prevent unnecessary pressure drops or flow restrictions. It's also vital to evaluate the installation position—whether the valve will be horizontal or vertical—as this can influence its functionality. Lastly, consider the maintenance requirements and accessibility; selecting a valve that is easy to inspect and service can save you time and costs in the long run, ensuring that your plumbing system operates efficiently.

Material Choices for Durability and Performance

When selecting a swing check valve for plumbing applications, the choice of material is crucial to ensure both durability and reliable performance. Common materials used in swing check valves include brass, stainless steel, and PVC. Each of these materials presents unique benefits and drawbacks that can significantly impact long-term efficiency and functionality. According to a report from the American Society of Plumbing Engineers (ASPE), the lifespan of brass and stainless steel valves can exceed 20 years in proper conditions, making them ideal for high-pressure systems and rigorous applications.

Brass is favored for its excellent corrosion resistance and ability to withstand high temperatures, making it suitable for heating systems. It offers a balance of weight and strength, which is essential for installations in various environments. On the other hand, stainless steel, noted for its superior chemical resistance, is often chosen for environments that expose the valve to harsh chemicals or extreme pressure situations, as highlighted in the 2021 Valve Manufacturing Industry Report. PVC valves provide a lightweight, cost-effective solution, particularly for residential plumbing. While they don’t hold up as well under high temperatures and pressures, their versatility in handling different fluids is noteworthy.

Ultimately, the choice of material not only affects the valve's operational efficiency but also its susceptibility to wear and tear, requiring careful consideration based on the specific plumbing needs and environmental factors. The right swing check valve, aligned with the appropriate materials, can lead to significant cost savings and enhanced performance in plumbing systems.

How to Choose the Right Swing Check Valve for Your Plumbing Needs - Material Choices for Durability and Performance

| Material | Durability | Temperature Resistance | Cost | Best Use Case |

|---|---|---|---|---|

| Brass | High | -20 to 200°C | Medium | Potable water systems |

| Cast Iron | Very High | -20 to 100°C | Low | Wastewater systems |

| PVC | Medium | 0 to 60°C | Low | Drainage systems |

| Stainless Steel | High | -20 to 250°C | High | Food processing |

| Bronze | High | -20 to 150°C | Medium | Marine applications |

Installation and Maintenance Tips for Swing Check Valves

When it comes to installing swing check valves, proper attention to detail is crucial for ensuring optimal performance and longevity. First, it's essential to select a suitable location for installation, ideally in a vertical position where gravity can assist in the valve’s operation. Before installation, make sure to clean the pipes thoroughly to remove any debris that might interfere with the valve's sealing capabilities. Always check the flow direction indicated on the valve, and ensure it aligns with the pipeline. Utilizing the right fittings and torque specifications during installation will help prevent leaks and potential damage to your plumbing system.

Maintenance of swing check valves is relatively straightforward but essential to maintain their functionality. Regular inspections should be conducted to check for any signs of wear or corrosion, as these can impede the valve’s performance. It is advisable to clean the valve periodically, especially if it is subject to debris-laden fluids. In the event of malfunction, such as leakage or inability to close, it may require disassembly for cleaning or part replacement. Additionally, ensure that pressure levels remain within the specified limits to avoid unnecessary strain on the valve, and consider consulting a professional if you encounter persistent issues, as this can help prevent more extensive plumbing problems down the line.

Related Posts

-

10 Best Ball and Globe Valves for Optimal Fluid Control in Industrial Applications

-

Top 10 Ball Valves You Need to Know for Your Next Project

-

How to Choose the Right Trunnion Ball Valve for Your Application

-

Unlocking the Benefits of Carbon Steel Ball Valves: A Comprehensive Guide to Selection and Usage

-

2025 How to Choose the Right Stainless Steel Valves for Your Industry Needs

-

Top 5 Benefits of Using Carbon Steel Ball Valves for Industrial Applications