How to Choose the Right Ball Check Valve for Your Plumbing Needs

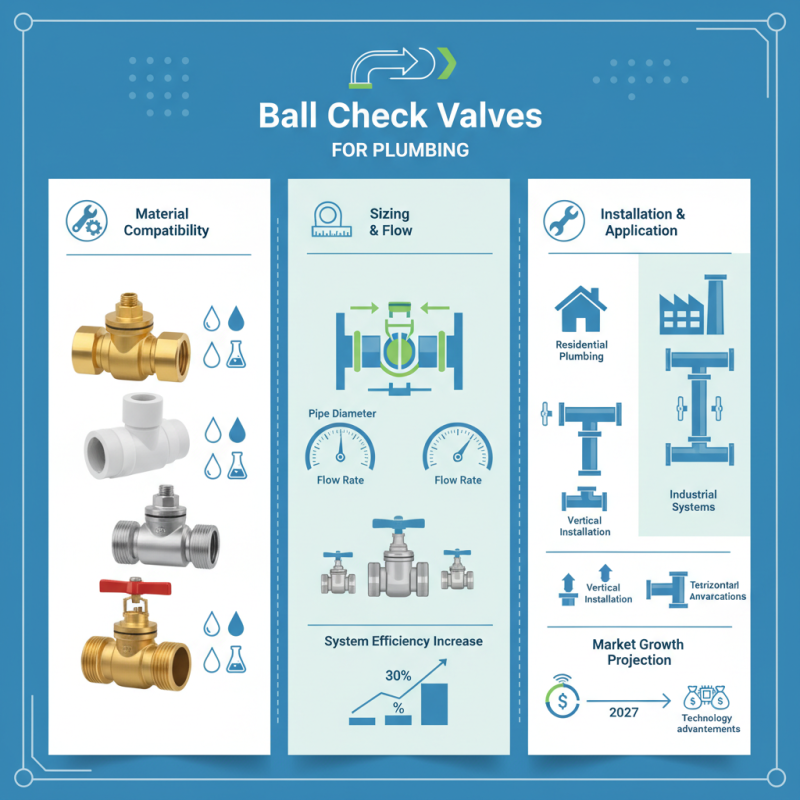

In the plumbing industry, the selection of the appropriate components plays a crucial role in ensuring system efficiency and reliability. Among these components, the ball check valve is often regarded as one of the most critical elements for controlling fluid flow and preventing backflow. According to a recent report by the International Association of Plumbing and Mechanical Officials (IAPMO), the proper selection and installation of valves can lead to a 30% increase in system efficiency, significantly reducing water wastage and potential maintenance costs over time.

As the demand for improved plumbing systems rises, understanding the specific requirements of a ball check valve becomes essential for both professionals and DIY enthusiasts. The market for valves is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2027, driven by advancements in technology and increasing infrastructure development. By choosing the right ball check valve, one can ensure optimal performance in various applications, from residential plumbing to industrial systems. This guide aims to equip readers with the knowledge necessary to select the most suitable ball check valve, considering factors such as material compatibility, sizing, and installation practices that align with prevailing industry standards.

Understanding the Functionality of Ball Check Valves in Plumbing

Ball check valves play a critical role in plumbing systems by preventing the backflow of water, ensuring efficiency and safety in domestic hot water applications. They operate based on the buoyancy of a ball that moves to block the flow of water when it attempts to reverse direction. This functionality is essential in maintaining consistent water pressure and preventing contamination of potable water supplies. Recent reports indicate that improper installation or selection of materials in plumbing fixtures can introduce harmful elements, such as lead, into drinking water. For instance, studies show that new brass plumbing devices can leach lead at levels exceeding 300 μg/L, underscoring the importance of choosing the right valve that meets safety and performance criteria.

When selecting a ball check valve, it is crucial to consider factors such as material, certification, and design features. The latest advancements in valve technology, including innovative designs that enhance usability and performance, are paving the way for safer plumbing solutions. Installers and homeowners should be aware that modern products now come equipped with advanced features that not only simplify the installation process but also ensure compliance with health and safety standards. Selecting a valve with fail-safe mechanisms can further mitigate risks, ultimately leading to a more reliable plumbing system. Adopting the right ball check valve is an investment in long-term safety and efficiency for any plumbing project.

Identifying Different Types of Ball Check Valves Available in the Market

When selecting a ball check valve for your plumbing needs, it’s essential to understand the different types available in the market. The most common types include plastic, brass, and stainless steel ball check valves.

Plastic valves are lightweight and resistant to corrosion, making them ideal for residential systems and applications involving chemical fluid transport.

On the other hand, brass valves offer enhanced durability and are most suitable for applications dealing with higher pressures and temperatures, frequently found in commercial settings.

Stainless steel ball check valves represent another category, known for their ability to withstand harsh environments and corrosive substances.

These valves are often utilized in industries such as food and beverage, pharmaceuticals, and wastewater treatment.

Additionally, one can also find specialty options like spring-assisted ball check valves, which help maintain a tighter seal and provide better flow regulation.

Understanding these variations is crucial to ensuring that you select a valve that meets the specific demands of your plumbing system.

Key Factors to Consider When Selecting a Ball Check Valve

When selecting a ball check valve for plumbing applications, there are several key factors to consider. Firstly, the valve's size and pressure rating are critical. It is essential to ensure that the valve can handle the flow rates and pressure conditions of your specific plumbing system. Miscalculating these parameters can lead to inefficiencies or system failures.

Another important aspect is the material of the ball check valve. Different materials offer varying levels of durability, resistance to corrosion, and compatibility with different fluids. For example, stainless steel valves may be ideal for corrosive environments, while PVC options might suffice for less demanding applications. Additionally, consider the ease of installation and maintenance of the valve; some designs may offer better accessibility for repairs and checks, contributing to long-term reliability in your plumbing system.

Sizing and Compatibility: Ensuring the Right Fit for Your Plumbing System

When selecting a ball check valve for your plumbing system, sizing and compatibility are critical factors that determine the valve's performance and longevity. According to the American Society of Mechanical Engineers (ASME), proper sizing ensures that the valve can handle the expected flow rates without excessive pressure loss, which could lead to inefficient operation. For most residential plumbing systems, it is recommended to choose a valve that matches the pipe diameter to maintain optimal fluid flow and prevent cavitation.

Tips: Measure your existing pipes carefully. The ball check valve should fit seamlessly with the pipe size. Most common sizes range from ½ inch to 6 inches, and knowing your system's requirements can save you time and costs associated with potential replacements or adjustments.

Additionally, check for compatibility with the materials used in your plumbing system. For instance, PVC valves are suitable for residential applications, while stainless steel options may be necessary for more corrosive environments. According to a report by the Hydraulic Institute, mismatched materials can lead to significant failure rates, underscoring the importance of using valves that align with pipe material specifications.

Tips: When in doubt, consult manufacturer guidelines or industry standards, as they provide valuable insights into material compatibility and performance expectations for various settings.

Common Applications and Benefits of Using Ball Check Valves

Ball check valves are essential components in various plumbing systems, offering numerous advantages that cater to a wide array of applications.

One common use is in drainage systems, where these valves prevent backflow and ensure that wastewater flows in the intended direction. This is crucial for maintaining hygiene and preventing contamination in fresh water lines.

Moreover, ball check valves are often employed in irrigation systems, helping to maintain a consistent water pressure while preventing siphoning, thus optimizing water usage and protecting the environment.

The benefits of using ball check valves extend beyond mere functionality; they are also renowned for their durability and ease of maintenance.

Made from robust materials such as brass or stainless steel, these valves can withstand harsh conditions, making them ideal for industrial applications where reliability is paramount.

Their simple design allows for easy cleaning and repair, minimizing downtime and maintenance costs. Additionally, their ability to handle a range of temperatures and pressures further establishes them as versatile tools in both residential and commercial plumbing, ensuring that users can rely on them for efficient and effective fluid control.

Related Posts

-

Unlocking the Benefits of Carbon Steel Ball Valves: A Comprehensive Guide to Selection and Usage

-

Top 5 Forged Valves: Best Options for Reliability and Performance

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

10 Essential Tips for Choosing the Right Trunnion Valve for Your System

-

The Essential Guide to Choosing the Right Floating Valve for Your Water Systems

-

Understanding the Essential Role of Trunnion Valves in Modern Industrial Applications