How to Choose the Right Stainless Steel Globe Valve for Your Needs?

When selecting the right stainless steel globe valve, expert Richard J. Smith emphasizes its importance in industrial applications. He once stated, "The right valve can make or break the efficiency of a system." This statement highlights the critical role of the stainless steel globe valve in fluid control.

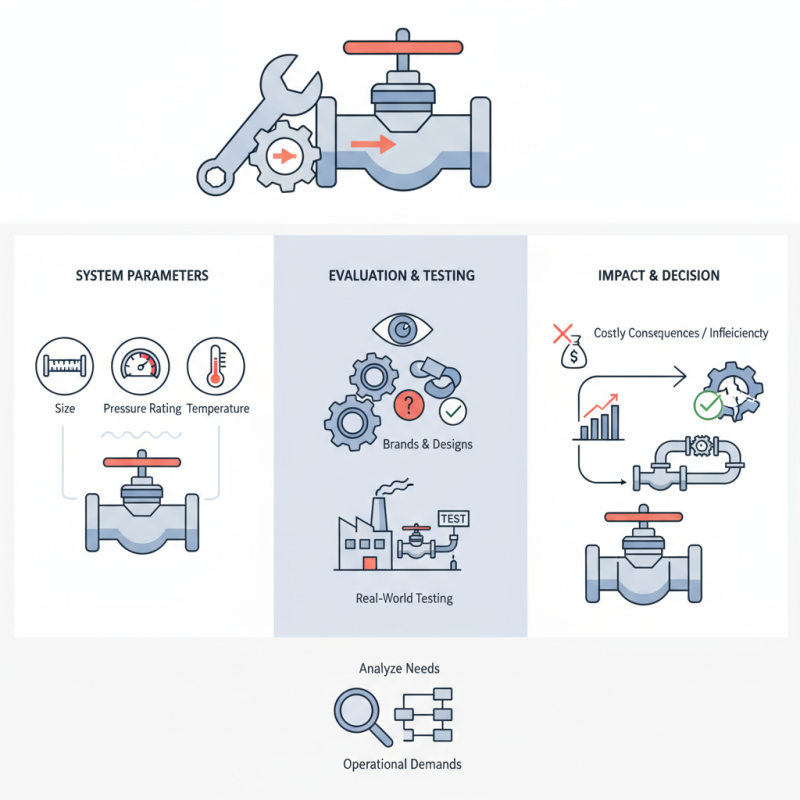

Choosing a stainless steel globe valve involves various factors. Consider the size, pressure rating, and temperature of your system. These specifications directly impact performance. A misstep in selection may lead to costly consequences.

Don't rush this decision. Evaluate different brands and designs. Some valves may visually appeal but perform poorly. Real-world testing will reveal their true capabilities. Analyze your needs carefully to ensure you choose the right stainless steel globe valve that meets your operational demands.

Understanding Stainless Steel Globe Valves and Their Applications

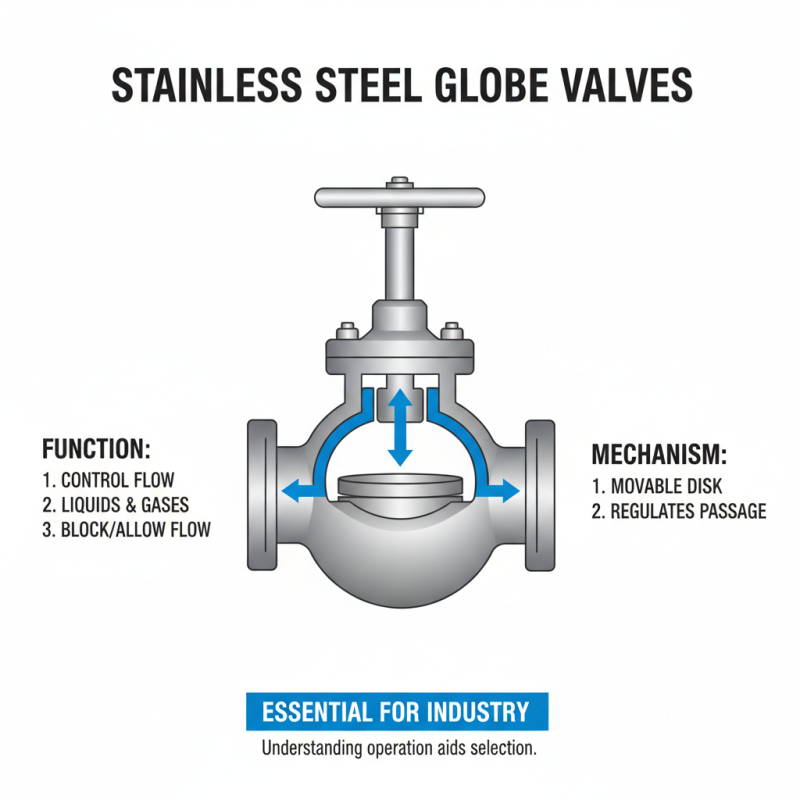

Stainless steel globe valves are essential in various industries. They control the flow of liquids and gases effectively. These valves function by using a movable disk that blocks or allows flow through the pipe. Understanding how they work helps in selecting the right type.

Applications of these valves vary widely. They are common in water supply systems, chemical processing, and oil and gas industries. A stainless steel valve is resistant to corrosion, making it ideal for harsh environments. However, not all stainless steel is made equal. Some grades offer better durability than others. Choosing the right grade can be tough, especially under pressure.

Installation and maintenance also require careful attention. Improper installation can lead to leaks or valve fatigue. Regular checks for signs of wear are crucial. Failures can incur high costs. It's important to evaluate usage frequency and pressure requirements. Each project might present unique challenges that require tailored solutions.

Key Factors to Consider When Selecting a Stainless Steel Globe Valve

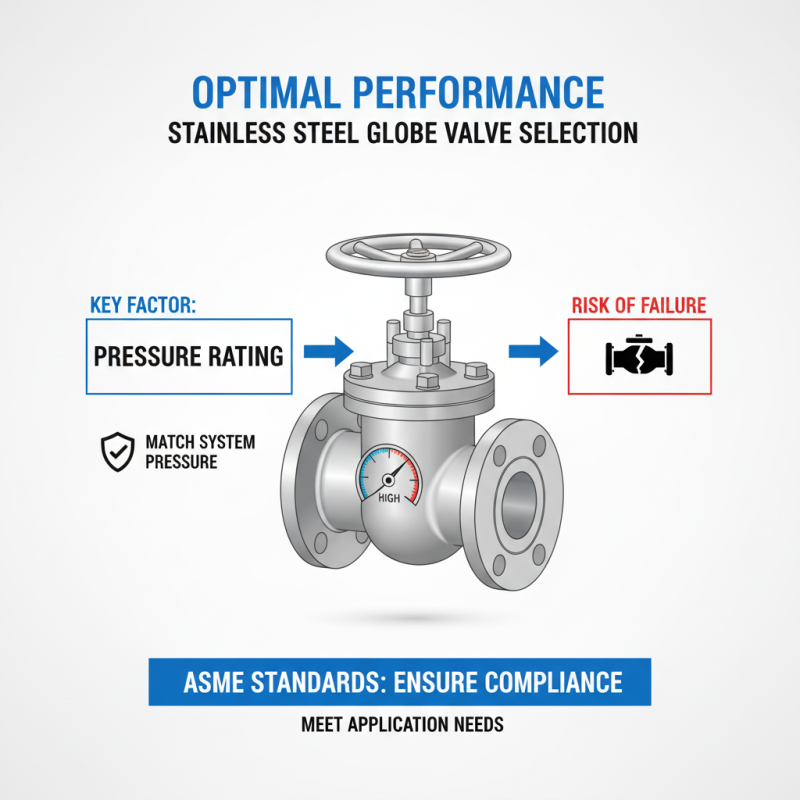

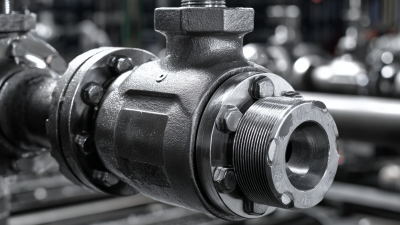

Choosing the right stainless steel globe valve is essential for optimal performance. One key factor is pressure rating. The American Society of Mechanical Engineers (ASME) indicates that valves must match system pressure. A mismatch can lead to failure. Look for valves that meet your specific application needs.

The material is also crucial. Stainless steel types vary in corrosion resistance. Choosing the wrong grade can result in premature wear. According to industry reports, 316 stainless steel is more resistant than 304 in harsh environments. Consider the fluid characteristics too. For instance, high temperature or chemical exposure can impact valve life.

Another important aspect is size and flow rate. Proper sizing ensures efficient operation. An oversized valve can cause turbulence. This issue may lead to energy loss. Research suggests that up to 30% of energy can be wasted this way. Selecting the right size involves verifying pipe dimensions and flow requirements. A detailed analysis is often necessary.

Types of Stainless Steel Globe Valves and Their Specific Uses

When selecting a stainless steel globe valve, understanding the various types and their specific applications is crucial. There are primarily two categories: standard globe valves and pressure-seal globe valves. Standard variants often suit less critical applications, while pressure-seal versions are designed for high-pressure requirements.

Standard globe valves are versatile. They are commonly used in water systems and low-pressure gas applications. According to industry reports, nearly 70% of globe valves fall into this category. However, they can have limitations in extreme conditions. Their design may restrict flow and create turbulence at high pressures.

On the other hand, pressure-seal globe valves excel in high-pressure environments. They have a unique sealing mechanism that enhances performance. Reports suggest that these valves can safely function in pressures exceeding 4,500 psi. Yet, they are often more expensive and may require meticulous installation. Engineers need to consider these factors carefully before making a decision.

Maintenance Tips for Ensuring Longevity of Your Globe Valve

Proper maintenance is crucial for the longevity of your stainless steel globe valve. Regular checks can prevent unforeseen failures.

Statistics show that nearly 30% of valve issues stem from neglect. Simple actions can extend the life of your valve. Ensure you perform routine inspections every six months.

Look for signs of wear, leakage, or corrosion. These are indicators that immediate action is needed.

Mind the operating conditions as well. Extreme temperatures and pressures can affect valve performance. According to industry reports, valves that operate outside their designed specifications can fail up to 40% faster. Adjustments may be necessary based on usage patterns. Tracking performance metrics over time can reveal trends that may require attention. Valves are critical components. Their maintenance impacts overall system reliability.

Common Mistakes to Avoid When Choosing a Globe Valve

Choosing the right stainless steel globe valve can be tricky. Many people make common mistakes that can lead to performance issues. One prevalent error is not considering flow characteristics. Globe valves are not always suitable for high flow applications. They create higher pressure drops, which can be a problem.

Another mistake is overlooking the material compatibility. Using the wrong stainless steel grade can cause corrosion or structural failure over time. According to a recent industry study, improper material selection leads to a 30% increase in maintenance costs. In some cases, valves failed within two years due to material issues.

It’s also important to evaluate the actuator method. Manual and automatic options each have their advantages. Many users forget about the size and power requirements of the actuator. Poor selection can affect how well the valve operates. Always check the specifications closely. A mismatched actuator can lead to inefficiencies that are costly in the long run.

Related Posts

-

Top 10 Stainless Steel Valves for Every Application You Need to Know

-

The Rising Demand for Globe Valves in Industrial Applications and Their Key Performance Metrics

-

Top 10 Benefits of Trunnion Mounted Ball Valve for Your Industrial Applications

-

Top 10 Industrial Valves Every Engineer Should Know About

-

The Essential Guide to Choosing the Right Floating Valve for Your Water Systems

-

Unlocking the Benefits of Carbon Steel Ball Valves: A Comprehensive Guide to Selection and Usage