Top 5 Best Ball Check Valves for Efficient Fluid Control?

In the realm of fluid control, a ball check valve plays a critical role. These devices prevent backflow, ensuring fluid flows in one direction. They are essential in various industries, including plumbing and oil systems.

An efficient ball check valve is designed for durability and reliable performance. However, not all valves are created equal. Some may struggle under high-pressure conditions. Others might wear out quickly. It's important to choose wisely.

The market offers many options. Evaluating features like material, size, and flow rates is key. Each valve presents unique strengths and weaknesses. Understanding these nuances can lead to better fluid management solutions. Investing time in research is worthwhile for effective operations.

Understanding the Functionality of Ball Check Valves in Fluid Systems

Ball check valves play a crucial role in fluid systems. They prevent backflow, ensuring that fluids flow in the correct direction. This functionality is vital in many applications, from wastewater treatment to industrial processes. According to a recent industry report, over 30% of fluid-related failures in systems can be traced back to improper valve selection. Choosing the right ball check valve can significantly reduce this risk.

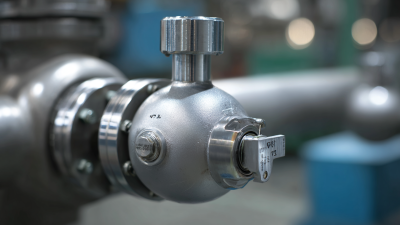

These valves utilize a spherical ball that moves with fluid pressure. When fluid flows in the intended direction, the ball elevates, allowing passage. However, if backflow occurs, the ball seats against the valve, blocking the reverse flow. This design principle is simple yet effective. However, improper installation can lead to failures. Regular assessments are needed to ensure they function properly.

Data from a fluid control survey indicates that companies optimizing their ball check valve systems can achieve up to a 15% increase in efficiency. However, it's essential to select valves based on specific application needs. Not every valve suits every system. This oversight can result in costly repairs and downtime. The selection process requires careful analysis and consideration of various factors.

Top 5 Best Ball Check Valves for Efficient Fluid Control

Key Features to Consider When Selecting Ball Check Valves

When selecting ball check valves, several key features come into play. Material choice is crucial. Common options include PVC, brass, and stainless steel. Each material has distinct advantages. For instance, stainless steel offers durability in harsh environments. It withstands corrosion but may also be more expensive. Likewise, the size of the valve matters. Ensure it fits your piping system perfectly. Incorrect sizing can lead to inefficiency or leaks.

Another important aspect is the pressure rating. Check valves must cater to the operating pressure of the system. A mismatch can cause failure. Often, users overlook this detail. Sometimes, they choose based on price rather than specifications. The sealing mechanism is also vital. A good seal prevents backflow and maintains system integrity. Consider whether a spring-loaded or gravity-operated mechanism works better for your needs.

Lastly, ease of maintenance shouldn’t be ignored. Some valves are more accessible than others. Valves that require frequent cleaning should be easy to disassemble. Regular checks can minimize potential issues down the line. Many users find maintenance daunting and procrastinate. This can lead to larger problems later. Evaluating these features will ensure better fluid control and extend the lifespan of your system.

Top 5 Recommended Ball Check Valves for Optimal Performance

When selecting a ball check valve, efficiency is key. These valves ensure proper fluid control in various applications. The right choice can enhance system performance. Look for features like durable materials and effective sealing. They can help prevent backflow and ensure smooth operation.

**Tip:** Consider the size and pressure ratings of the valve. Choosing one that fits your system is crucial. Misjudging this could lead to inefficient fluid flow.

Maintenance is essential for optimal performance. Regular inspections can help prevent leaks or blockages. If you notice any irregularities, address them immediately. Ignoring small issues can lead to bigger, costly problems.

**Tip:** Always match the valve to the fluid type. Different fluids can have varying effects on materials. Understanding this will prolong the life of your valve.

Comparative Analysis of Ball Check Valves: Pros and Cons

When exploring ball check valves, understanding their pros and cons is crucial. These valves are renowned for their simple design and efficient one-way flow control. They usually consist of a ball that seals against an opening. This prevents backflow and maintains system integrity. However, they can present maintenance challenges. Dirt and debris can hinder the ball's movement.

One of the key advantages is reliability. Ball check valves are sturdy and can handle high pressures. They are less prone to sticking compared to other valve types. Despite this, they may not be ideal for all applications. For example, in low flow situations, they might not seal properly. This can lead to potential leakage.

Tips: Always assess your system's specific fluid dynamics. Consider the operating pressure and flow rate. This will ensure optimal performance. Regular cleaning can help mitigate some common issues. Ensuring the valves are regularly serviced will lead to longer service life. Proper installation is also vital. An incorrectly installed valve may not function as intended. Understanding these nuances is essential for efficient fluid control.

Maintenance Tips to Enhance the Longevity of Ball Check Valves

Ball check valves are essential for fluid control in various systems. To ensure they work efficiently, regular maintenance is crucial. One simple task is to inspect them frequently for any signs of wear. This helps catch small issues before they become significant problems.

Cleaning the valves is another important step. Debris can build up over time, affecting performance. A quick rinse with water may be sufficient. However, stubborn deposits may require a more thorough cleaning with appropriate solvents. Make sure to ensure all parts are dry before reinstallation.

Checking for proper alignment is vital. Misalignment can lead to malfunctioning or complete failure. Regular inspections can prevent unnecessary repairs. Observing any irregular noises during operation can also help gauge the valve's health. These simple maintenance tips can enhance the longevity of ball check valves significantly, ensuring reliable fluid control.

Top 5 Best Ball Check Valves for Efficient Fluid Control

| Model | Material | Size | Max Pressure (PSI) | Temperature Range (°F) |

|---|---|---|---|---|

| Model A | Stainless Steel | 2 inch | 150 | -20 to 250 |

| Model B | Brass | 1.5 inch | 200 | -10 to 230 |

| Model C | PVC | 3 inch | 75 | 0 to 140 |

| Model D | Aluminum | 2.5 inch | 100 | -20 to 175 |

| Model E | Cast Iron | 4 inch | 250 | -10 to 300 |

Maintenance Tips to Enhance the Longevity of Ball Check Valves

- Regularly inspect for leaks and corrosion.

- Clean the valve periodically to prevent debris buildup.

- Ensure proper installation to avoid backflow and misalignment.

- Use strainers to protect the valve from particle debris.

- Test the valve function regularly to ensure reliability.

Related Posts

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

10 Best Ball and Globe Valves for Optimal Fluid Control in Industrial Applications

-

Top 10 Ball Valves for Industrial Applications You Should Consider

-

2025 Top Insights: Ball Valve vs Globe Valve - Which is Best for Your Project?

-

The Best 10 Ball Check Valve Options for Efficient Fluid Control

-

Top 10 Benefits of Trunnion Mounted Ball Valve for Your Industrial Applications