The Best 10 Ball Check Valve Options for Efficient Fluid Control

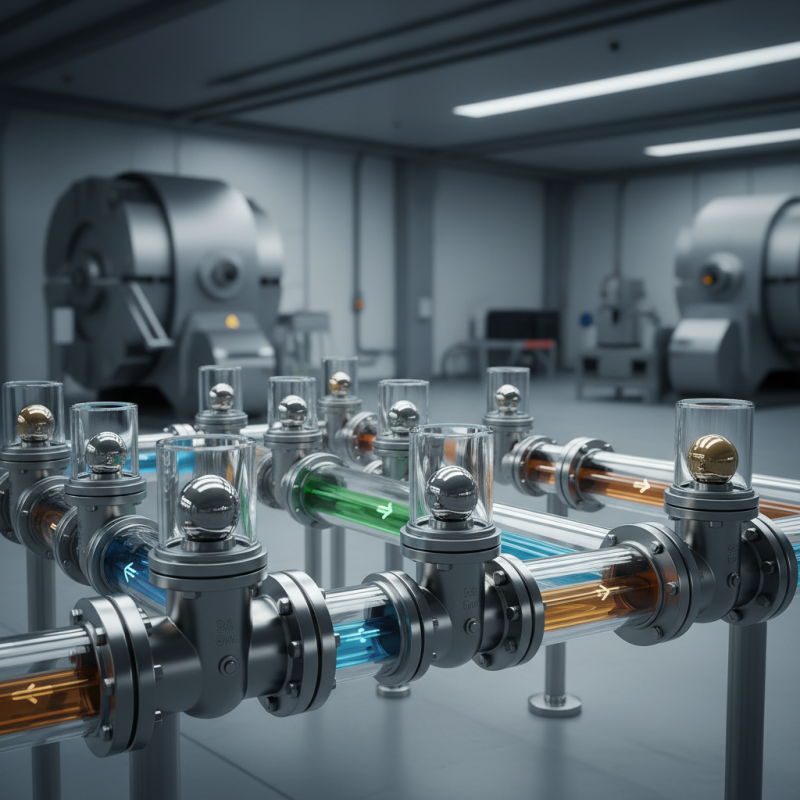

When it comes to managing fluid flow in various systems, the choice of valve is critical for ensuring efficiency and reliability. Among the different types of valves available, the ball check valve stands out for its unique design and functionality. By allowing fluid to flow in one direction while preventing backflow, a ball check valve plays an essential role in maintaining system integrity and optimizing performance.

In industries ranging from water treatment to chemical processing, the selection of the right ball check valve can significantly impact the overall efficiency of fluid control mechanisms. With numerous options available in the market, making an informed choice can be daunting. This article aims to streamline that process by exploring the best 10 ball check valve options that excel in performance and reliability. By highlighting their key features, applications, and benefits, readers will gain insight into how to enhance their fluid control systems with the most suitable ball check valve solutions.

Understanding the Functionality of Ball Check Valves in Fluid Control

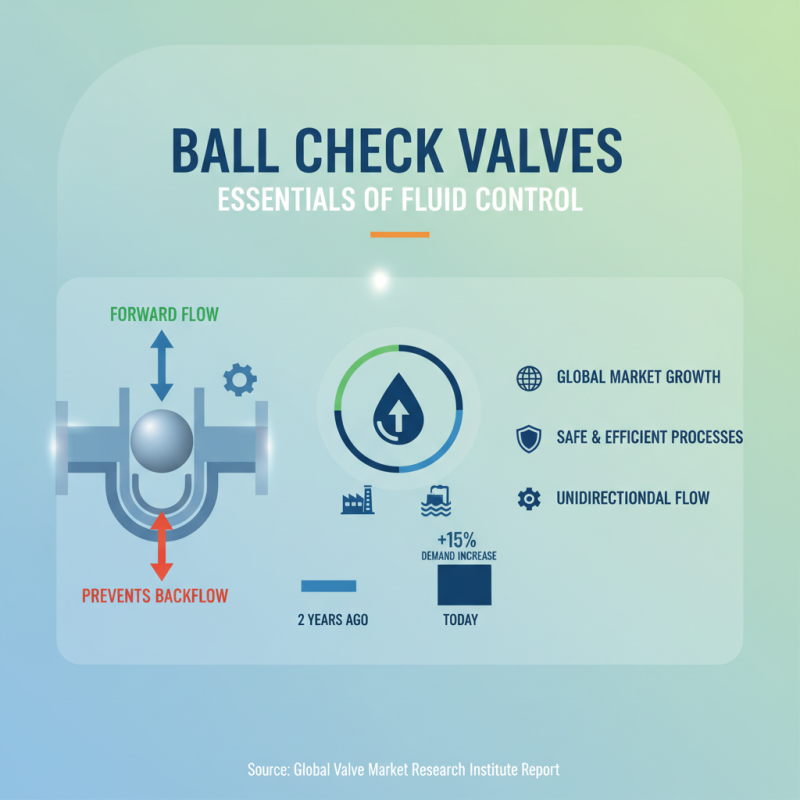

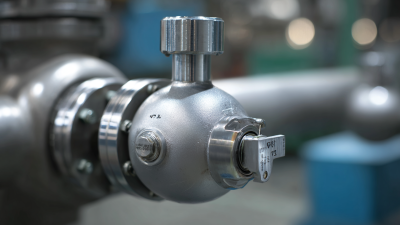

Ball check valves play a critical role in fluid control systems, allowing for the unidirectional flow of liquids while preventing backflow. Their design features a spherical disc that seals off the valve when fluid attempts to reverse direction, ensuring that processes remain safe and efficient. According to a recent report from the Global Valve Market Research Institute, the demand for efficient fluid control solutions has increased by over 15% in the past two years, underscoring the necessity of effective components such as ball check valves in various applications.

One of the primary benefits of ball check valves is their minimal pressure drop across the valve, which can enhance operational efficiency. They are commonly used in environments where consistent fluid flow is essential, such as in water treatment plants and industrial manufacturing systems. The unique design allows for quick response times, making them ideal for dynamic applications where flow rates can change rapidly.

Tips: When selecting a ball check valve, consider factors such as the size, material compatibility, and pressure rating to ensure optimal performance for your specific application. Regular maintenance is also vital—inspecting valves for wear or blockage can significantly extend their lifespan and functionality. Understanding these elements will help you make informed decisions and maintain fluid control systems effectively.

Key Features to Consider When Selecting a Ball Check Valve

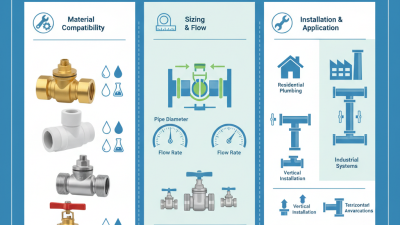

When selecting a ball check valve for efficient fluid control, there are several key features to consider to ensure optimal performance. First, the valve's material is crucial; it should ideally be compatible with the fluids it will handle. Common materials include stainless steel, brass, and plastics, each offering different levels of corrosion resistance and pressure handling capabilities. Additionally, the size and flow capacity of the valve should match the system’s requirements. An undersized valve may restrict flow and create pressure drops, while an oversized valve could lead to inefficient operation.

Tips for selection:

- Always evaluate the working pressure and temperature of your application; this will help ensure the chosen valve can withstand operational conditions without failure.

- Pay attention to the sealing mechanism; high-quality seals can prevent leakage and ensure reliability over time.

Another important feature to consider is the valve design itself. Consider whether a spring-loaded or free-floating design is more suitable for your application. Spring-loaded designs offer better sealing capabilities at lower pressures, while free-floating designs are ideal for higher flow rates. Additionally, the ease of maintenance and installation should not be overlooked—choosing valves with accessible components can save you time and resources in the long run.

Tips for maintenance:

- Regularly inspect the ball and seat area to prevent build-up that could impede function.

- Ensure that any sealing materials are regularly checked and replaced as needed to maintain effective operation.

The Best 10 Ball Check Valve Options for Efficient Fluid Control

| Model | Material | Connection Type | Size (inch) | Max Pressure (psi) | Temperature Range (°F) |

|---|---|---|---|---|---|

| Model A | Brass | Threaded | 1 | 150 | -40 to 180 |

| Model B | PVC | Socket | 2 | 100 | -20 to 140 |

| Model C | Stainless Steel | Flanged | 3 | 250 | -40 to 400 |

| Model D | Polypropylene | Threaded | 1.5 | 150 | -40 to 170 |

| Model E | Bronze | Flanged | 4 | 200 | 0 to 300 |

| Model F | PVC | Socket | 3 | 80 | -20 to 120 |

| Model G | Stainless Steel | Threaded | 2.5 | 300 | -40 to 500 |

| Model H | Brass | Flanged | 5 | 300 | -20 to 250 |

| Model I | Polypropylene | Threaded | 2 | 100 | -40 to 150 |

| Model J | Bronze | Socket | 1 | 250 | 0 to 200 |

Top 10 Ball Check Valve Options for Various Applications

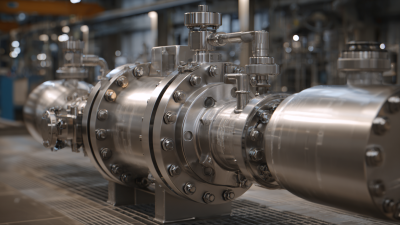

When it comes to fluid control in various applications, choosing the right ball check valve is paramount to ensuring efficiency and reliability. Ball check valves are designed to prevent backflow in piping systems while allowing unobstructed flow in one direction. Their versatility makes them suitable for a wide range of industries, including water treatment, HVAC systems, and chemical processing. Understanding the specific needs of your application, such as pressure ratings, flow rates, and material compatibility, is essential in selecting the most appropriate valve.

Among the key options available, consider factors such as size, body material, and sealing mechanism. For high-corrosive environments, valves made from stainless steel or specialized plastics can offer enhanced durability. Additionally, valves with silicone seals are ideal for applications requiring high hygiene standards, commonly found in food and beverage production. Furthermore, assessing the installation orientation is crucial, as some designs function better in vertical installations while others are optimized for horizontal flow. By evaluating these parameters, you can identify the best ball check valve to ensure seamless operation and longevity in your specific application.

Comparative Analysis of Material Types for Ball Check Valves

When selecting a ball check valve for efficient fluid control, the choice of material significantly influences performance, durability, and applicability across various industries. Typically, ball check valves are available in materials such as brass, stainless steel, and plastic, each offering distinct advantages. A recent industry report indicates that stainless steel valves, known for their strength and resistance to corrosion, are increasingly favored in applications involving aggressive fluids. This material can withstand higher pressures and is compatible with a wider range of temperatures, making it suitable for critical environments, including chemical processing and petrochemical operations.

On the other hand, brass ball check valves are recognized for their excellent thermal conductivity and lower cost, making them an attractive option for standard applications in HVAC systems and water supply lines. According to market analysis, the demand for plastic ball check valves has escalated, particularly in agricultural and water treatment applications, due to their lightweight nature and resistance to chemicals. With advancements in polymer technology, these valves can now handle moderate pressure and temperature variations, offering a cost-effective solution without compromising on performance. Ultimately, choosing the correct material not only enhances the functionality of ball check valves but also contributes to extended service life and reliability in fluid control systems.

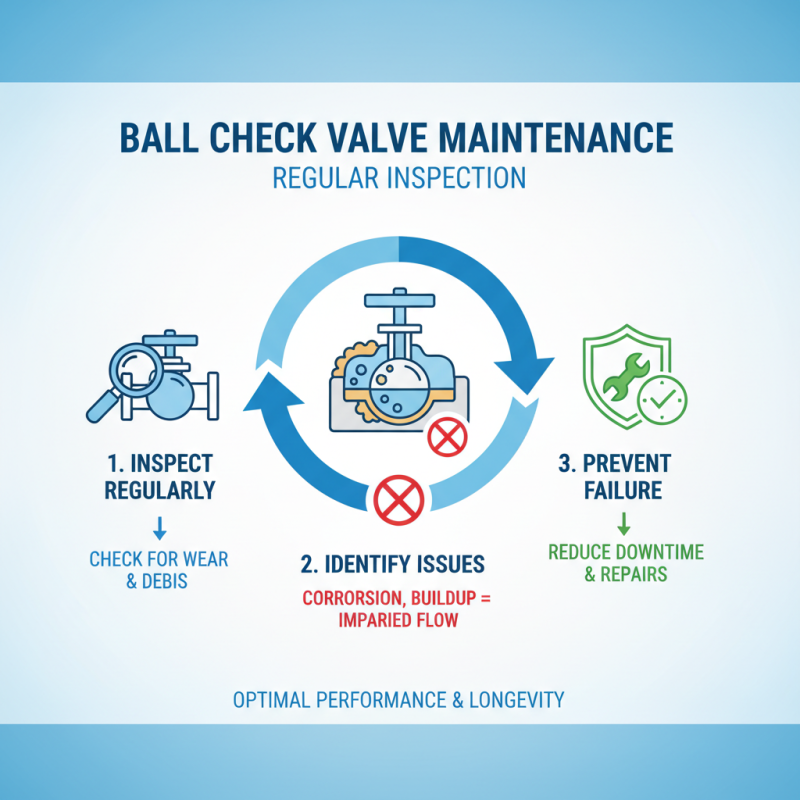

Maintenance Tips for Ensuring Optimal Performance of Ball Check Valves

Maintaining ball check valves is essential to ensure their optimal performance and longevity. Regular inspection is one of the key maintenance practices. This involves checking for any signs of wear, such as corrosion or buildup of debris, which can impede the valve’s operation. By performing routine inspections, operators can identify potential issues before they escalate, preventing costly downtime and repairs.

Another important aspect of maintenance is ensuring that the installation and operating conditions are adhered to. The valve should be installed in the correct orientation, as improper positioning can lead to malfunction. Moreover, monitoring the fluid characteristics, including temperature and pressure, is crucial. Maintaining the fluid conditions within the recommended parameters ensures that the ball check valve functions efficiently.

Additionally, periodic cleaning is vital to remove any accumulated residues that may affect performance. Depending on the application, a simple cleaning routine can significantly enhance the valve’s effectiveness. Regular maintenance and attention to the operational environment will help in achieving a reliable and efficient fluid control system with ball check valves.

Related Posts

-

Unlocking the Benefits of Carbon Steel Ball Valves: A Comprehensive Guide to Selection and Usage

-

10 Best Ball and Globe Valves for Optimal Fluid Control in Industrial Applications

-

How to Choose the Right Ball Check Valve for Your Plumbing Needs

-

2025 Top Insights: Ball Valve vs Globe Valve - Which is Best for Your Project?

-

Top 10 Benefits of Trunnion Mounted Ball Valve for Your Industrial Applications

-

Understanding the Essential Role of Trunnion Valves in Modern Industrial Applications