Top 10 Benefits of Trunnion Mounted Ball Valve for Your Industrial Applications

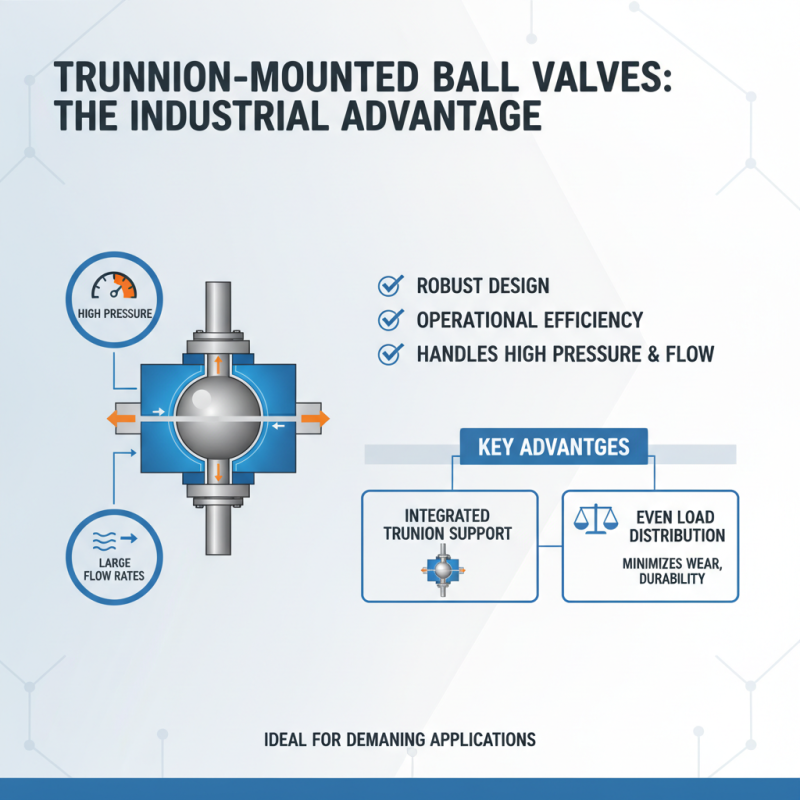

In the realm of industrial applications, the choice of a reliable valve system is crucial for maintaining efficiency and safety. Among the various types of valves available, the trunnion mounted ball valve stands out for its unique design and operational advantages. This valve configuration features a ball supported by trunnions, providing stability and minimizing wear and tear, which significantly enhances its performance. As industries strive for optimal functionality, the trunnion mounted ball valve offers numerous benefits that can lead to improved operational efficiency and reduced maintenance costs.

The robust construction of trunnion mounted ball valves allows them to handle high pressures and large flow rates, making them ideal for diverse industrial applications, from oil and gas to water treatment. Their design not only facilitates a tight seal but also enables them to operate under extreme conditions, ensuring longevity and reliability. As we delve into the top ten benefits of using trunnion mounted ball valves, it becomes evident how their features can lead to enhanced productivity and cost-effectiveness, affirming their status as an indispensable component in modern industrial environments.

Top Advantages of Trunnion Mounted Ball Valves in Process Control

Trunnion mounted ball valves are increasingly favored in industrial process control due to their robust design and operational efficiency. One of the primary advantages of these valves is their ability to handle high pressures and large flow rates. The integrated trunnion design ensures that the ball is supported both at the top and bottom, which distributes the load evenly and minimizes wear over time. This feature is particularly advantageous in demanding applications, where pressure fluctuations are common.

Another significant benefit of trunnion mounted ball valves is their excellent sealing capability. These valves utilize a soft seal mechanism that ensures a tight closure, preventing leakage and enhancing safety in processing environments. Additionally, the low operating torque required to open and close the valve makes them ideal for automation, allowing for seamless integration with control systems. This versatility enables precise control of flow rates and enhances overall process reliability, making trunnion mounted ball valves a vital component in various industrial applications, from oil and gas to chemical processing.

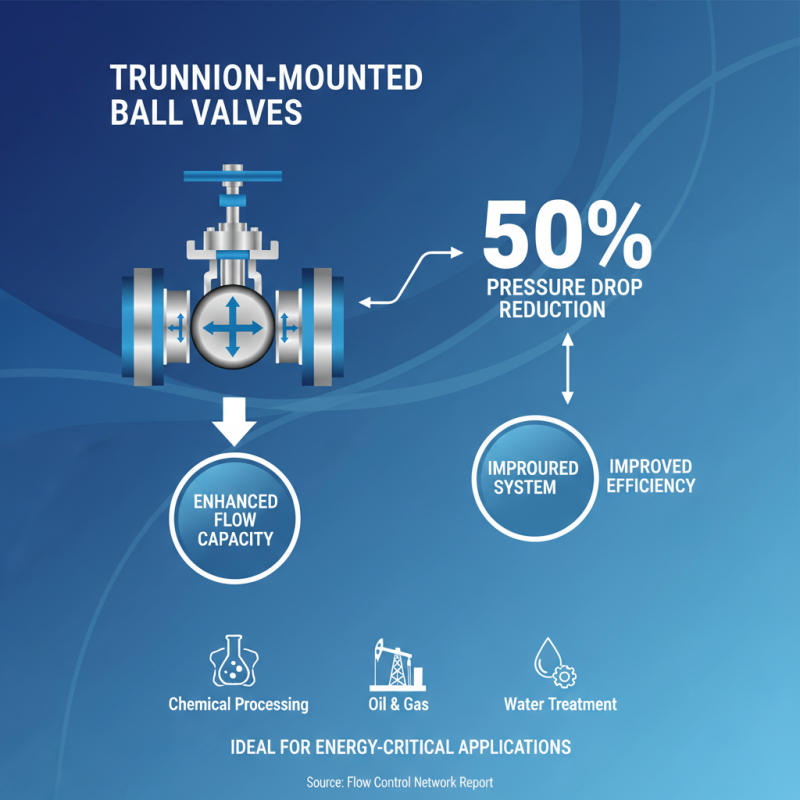

Enhanced Flow Capacity and Reduced Pressure Drop in Industrial Systems

Trunnion mounted ball valves are increasingly recognized for their capability to enhance flow capacity and reduce pressure drop in industrial systems. According to a report by the Flow Control Network, the use of these valves can lead to a pressure drop reduction of up to 50%, improving overall system efficiency. This efficiency gain is critical in applications where minimizing energy consumption and optimizing flow are of utmost importance, such as in chemical processing, oil and gas, and water treatment industries.

One significant advantage of trunnion mounted ball valves is their design, which allows for a robust support system that minimizes the wear and tear seen in traditional valve types. This enhances the stability and longevity of the valve, contributing further to a consistent flow rate under varying pressure conditions. In a study published by the Journal of Pressure Vessel Technology, it was noted that facilities adopting these valves reported a 30% reduction in maintenance costs over five years due to their durability and reliability.

**Tip:** When selecting trunnion mounted ball valves, ensure to consider the specific flow requirements and pressure levels of your application. Conducting a thorough analysis and consulting industry standards can lead to improved operational efficiency.

**Tip:** Regularly schedule maintenance checks on your valve systems, even for robust designs like trunnion mounted ball valves, to prevent unexpected downtime and to maximize their operational capacity.

Durability and Longevity: A Study on Material Performance in Harsh Environments

Trunnion mounted ball valves are increasingly favored in industrial applications due to their unique design and robust performance in harsh environments. The fundamental construction of these valves includes a ball that is supported at both the top and bottom, providing enhanced stability and reduced wear over time. Research conducted by the American Society of Mechanical Engineers (ASME) highlights that trunnion mounted valves can withstand extreme pressure fluctuations and temperature variations, making them particularly suitable for sectors such as oil and gas, petrochemical, and water treatment.

In terms of material performance, studies demonstrate that trunnion mounted ball valves can maintain their integrity even when exposed to corrosive substances or elevated temperatures. For instance, a recent report from the Chemical Engineering Research Group indicated that valves made from high-grade stainless steel exhibited less than 2% degradation in harsh acidic environments over a five-year period. This level of durability not only extends the lifecycle of the equipment but also reduces maintenance costs significantly—by as much as 25% according to industry assessments. Consequently, the durability and longevity of trunnion mounted ball valves position them as a critical asset in maintaining operational efficiency across various industrial applications.

Ease of Maintenance and Refurbishment: Cost Analysis and Strategies

Trunnion mounted ball valves have gained popularity in various industrial applications due to their advantages in maintenance and refurbishment. One key benefit is the ease of serviceability they offer. According to a report from the International Society of Automation, valves account for approximately 15% of the total maintenance costs in industrial settings. By using trunnion mounted designs, companies can significantly reduce the time and labor required for valve maintenance. Their design allows for easy access to key components without needing to remove the valve from the pipeline, which minimizes downtime and leads to considerable savings.

When considering a cost analysis for maintenance strategies, it is essential to note that the long-term savings from enhanced durability and reduced need for spare parts can be substantial. A study by the American Council of Engineering Companies indicated that proactive maintenance planning using trunnion mounted ball valves can lead to a 20% decrease in overall operational costs. Regular assessments and timely refurbishments ensure that any deterioration is addressed before it evolves into a critical failure, further extending valve life.

Tips: Regularly scheduled inspections can help identify wear and tear in trunnion mounted ball valves, allowing for timely maintenance interventions. Additionally, staff training on proper valve operation can enhance the longevity of these components. Implementing a digital maintenance management system improves tracking and scheduling, ensuring that all maintenance activities are executed efficiently without interrupting production.

Top 10 Benefits of Trunnion Mounted Ball Valve

This chart illustrates the importance of various benefits associated with Trunnion Mounted Ball Valves in industrial applications. Each benefit is rated on a scale from 0 to 100, showcasing their relative significance.

Safety and Efficiency: Industry Standards for Trunnion Mounted Ball Valves

Trunnion mounted ball valves are designed to meet stringent industry standards, enhancing both safety and efficiency across various industrial applications. Their robust construction ensures that they can handle high pressures and temperatures, making them ideal for critical processes where reliability is paramount. Additionally, these valves feature a mounting system that reduces stress on the ball and stem, leading to prolonged lifespan and reduced maintenance costs. This characteristic not only optimizes operational efficiency but also aligns with safety regulations that demand the highest performance levels.

When selecting trunnion mounted ball valves for your operations, consider adopting best practices to ensure safety and performance. One tip is to perform regular inspections and maintenance checks to detect any signs of wear or leakage early on. Another important aspect is to ensure that the valves are installed correctly, following manufacturer guidelines and industry standards to minimize risks associated with valve failures. Proper training for personnel on the correct operation and troubleshooting techniques can further enhance safety and efficiency, keeping operations running smoothly and safely.

Related Posts

-

Top 10 Reasons Why Steel Ball Valves Are Essential for Your Industrial Applications

-

Unlocking the Benefits of Carbon Steel Ball Valves: A Comprehensive Guide to Selection and Usage

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

2025 How to Choose the Right Steel Ball Valve for Your Industrial Needs

-

What is a Stainless Steel Globe Valve and Its Key Benefits for Industries

-

Exploring the Future of Industrial Valves: Innovations and Trends Shaping the Industry