Top 10 Benefits of Floating Ball Check Valves You Need to Know

In the ever-evolving world of fluid control solutions, the floating ball check valve stands out as a pivotal component for various industrial applications. According to a report by Global Market Insights, the floating ball check valve market is projected to reach $2.1 billion by 2027, driven by the increasing demand for efficient and reliable fluid management systems. This sector is characterized by its innovative designs that enhance operational efficiency and reduce maintenance costs.

Dr. Emily Hart, a renowned expert in valve technology, emphasizes the critical role of floating ball check valves, stating, "The unique design of the floating ball check valve not only prevents backflow but also minimizes pressure loss, making it indispensable for modern fluid systems." With ten key benefits ranging from improved durability and corrosion resistance to simplified maintenance and enhanced performance, understanding the advantages of floating ball check valves is essential for engineers and decision-makers in the industry. As we delve into the top 10 benefits of floating ball check valves, we will uncover how these devices streamline processes and contribute to overall operational excellence.

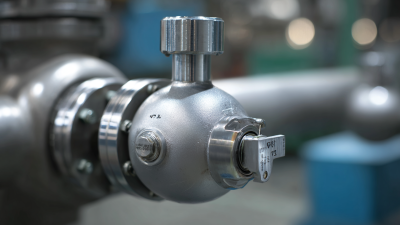

Advantages of Floating Ball Check Valves in Fluid Control Systems

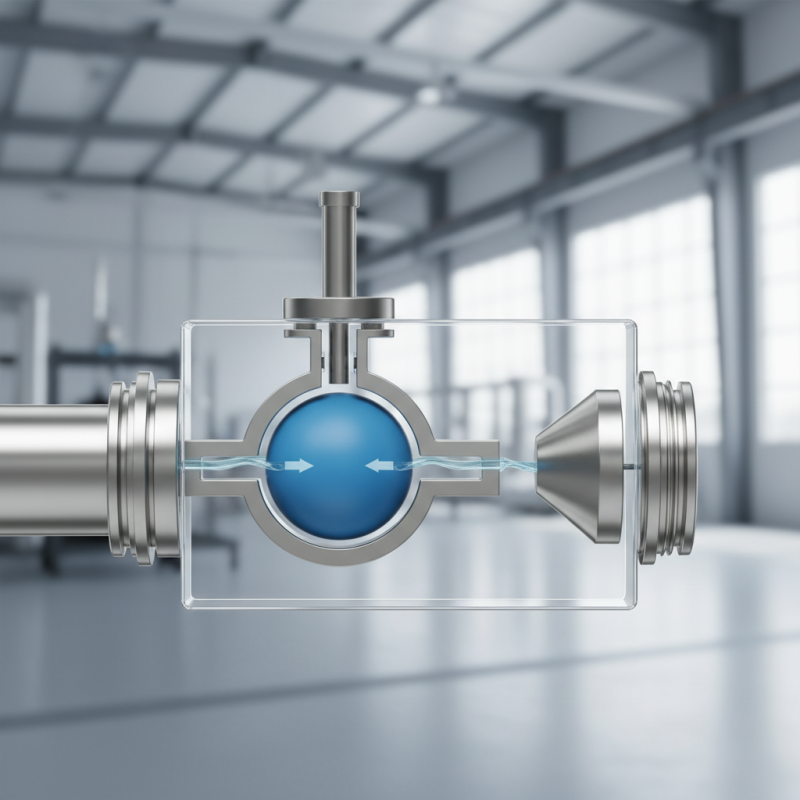

Floating ball check valves are essential components in fluid control systems, offering numerous advantages that enhance their performance and reliability. One of the primary benefits is their ability to prevent backflow effectively. The floating ball mechanism responds to the flow direction, allowing fluid to pass through easily while automatically sealing off the reverse flow, thus protecting pumps and other equipment from potential damage.

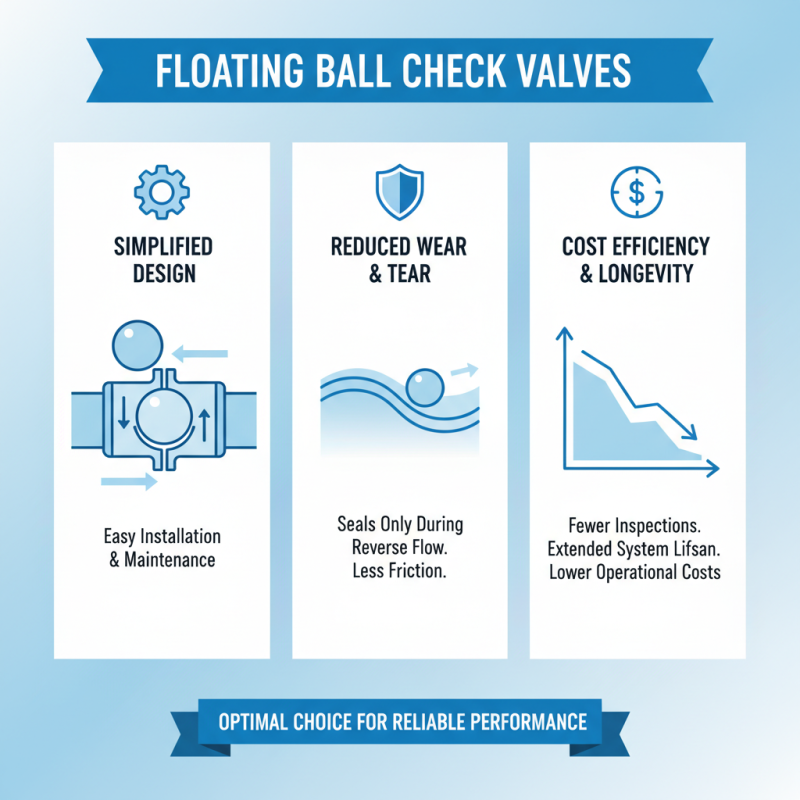

Furthermore, floating ball check valves are known for their simplicity and low maintenance requirements. Their design minimizes the risk of wear and tear, which can be a concern with more complex valve types. This low-friction operation means that, even under varying pressure levels, the valve can function smoothly and maintain its sealing capabilities. Additionally, they can handle a wide range of fluid types, making them highly versatile for various applications in industries such as water treatment, chemical processing, and oil and gas.

Enhanced Reliability of Floating Ball Check Valves for Backflow Prevention

Floating ball check valves are increasingly recognized for their enhanced reliability in preventing backflow, a critical consideration in various industrial applications. Their design features a buoyant ball that effectively seals off flow when the fluid attempts to reverse direction. This simple yet effective mechanism ensures that fluids only flow in one direction, significantly reducing the risk of contamination and maintaining system integrity.

One of the key advantages of floating ball check valves is their ability to self-adjust to varying pressure conditions. This adaptability makes them particularly useful in environments where fluid dynamics may fluctuate, as they can maintain a firm seal even under varying pressures, preventing reverse flow. Furthermore, their low maintenance requirements contribute to operational reliability, allowing facilities to minimize downtime and maintenance costs. This reliability is further enhanced by the durable materials used in their construction, which can withstand harsh conditions, ensuring longevity and consistent performance over time.

Maintenance Benefits of Using Floating Ball Check Valves

Floating ball check valves offer significant maintenance advantages, making them an optimal choice for various applications. One of the primary benefits is their straightforward design, which contributes to easier installation and maintenance processes. The floating ball mechanism allows for the valve to seal effectively only when there is a reverse flow, reducing wear and tear on components. This feature minimizes the need for frequent inspections and replacements, helping to lower operational costs and extend the overall lifespan of the system.

Additionally, floating ball check valves are less prone to clogging compared to other valve types, as their unique mechanism allows for self-cleaning during operation. This reduces the likelihood of buildup within the valve, which can lead to malfunctions. By maintaining a consistent flow and effectively preventing backflow, these valves help safeguard the integrity of associated equipment, which further decreases maintenance requirements. Ultimately, adopting floating ball check valves can lead to smoother operations with less downtime, making them an efficient choice for maintenance-conscious environments.

Floating Ball Check Valves: Key Features That Improve Performance

Floating ball check valves offer several key features that significantly improve performance in various applications. One of the most notable advantages is their ability to prevent backflow effectively. The floating ball mechanism allows for a quick response to changes in flow direction, ensuring that liquid travels in the intended direction without any interference. This reduces the risk of contamination and protects the integrity of the system, especially in critical environments such as water treatment facilities and industrial processes.

Another important feature is the self-cleaning capability of floating ball check valves. The design minimizes the potential for debris accumulation, which can hinder valve performance over time. This self-cleaning action is particularly beneficial in applications with fluctuating flow rates, as it helps maintain optimal efficiency and reduces maintenance costs. By incorporating these valves, operators can expect extended service life and less downtime due to repairs.

Tips: When selecting floating ball check valves for your project, consider the specific flow conditions and the type of media being handled. Ensure that the material compatibility is suitable for your application to prevent premature wear. Regularly inspecting the valves can also help identify any potential issues early on, allowing for timely interventions before they escalate into more significant problems.

Cost-Effectiveness of Floating Ball Check Valves in Industrial Applications

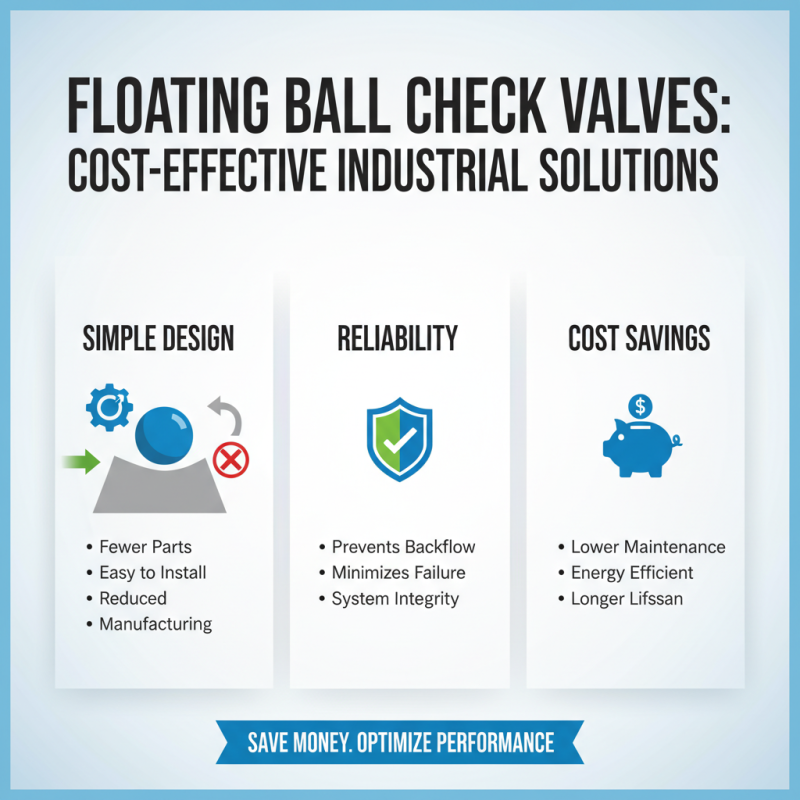

Floating ball check valves are increasingly recognized for their cost-effectiveness in various industrial applications. By design, these valves allow fluid to flow in one direction while preventing backflow, thus ensuring system integrity without the need for complex mechanisms. The simplicity of the floating ball design not only reduces manufacturing and maintenance costs but also minimizes the potential for mechanical failure. As a result, companies can achieve significant savings in installation and operational expenses over the life of the equipment.

In addition to their initial affordability, floating ball check valves contribute to enhanced operational efficiency. Their low-pressure drop characteristics lead to improved flow rates, which can translate into reduced energy consumption. Moreover, their reliable performance decreases the likelihood of downtime due to valve failure, allowing industries to maintain productivity levels while saving on repair and replacement costs. This combination of durability and efficiency makes floating ball check valves an attractive choice for businesses looking to optimize their budgets without compromising on quality.

Related Posts

-

How to Choose the Right Ball Check Valve for Your Plumbing Needs

-

10 Best Ball and Globe Valves for Optimal Fluid Control in Industrial Applications

-

Top 10 Ball Valves You Need to Know for Your Next Project

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

Exploring the Future of Industrial Valves: Innovations and Trends Shaping the Industry

-

Top 5 Benefits of Using Carbon Steel Ball Valves for Industrial Applications